How Thick Are Concrete Slab Foundations for Commercial Use?

The success of any building project starts with the foundation. Concrete slab foundations may seem straightforward, but their performance depends on proper planning, skilled construction, and the correct slab thickness.

As with any structural element, everything begins with following the appropriate engineering requirements and building codes. One of the most critical specifications is the required foundation depth. This thickness isn’t arbitrary. It’s determined by a range of factors and established standards.

To help you understand what your project truly needs, this post breaks down how thick a concrete slab foundation should be. Additionally, we will discuss the factors that influence that decision and guide you through the steps for proper construction.

Proper slab thickness can’t be guessed or determined by just anyone. It requires experts who understand soil behavior, load demands, and local code requirements. If you’re in Southern California,

contact the professionals

at TMC Engineering. Our experienced team can assess your property, determine a safe slab thickness, and provide a reliable quote for your foundation construction.

How Thick Are Concrete Slab Foundations for Commercial Use?

In commercial construction, concrete slabs anchor every aspect of the building process. However, many business owners and property managers consider alternatives that lack the structural reliability necessary for commercial applications.

Concrete remains the most durable, cost-effective, and sustainable solution for long-term performance. Equally important is partnering with contractors who bring the technical expertise and commercial experience necessary to meet regulation and code requirements.

In this guide, we explain what a concrete slab foundation is and outline the average slab depths. We also outline how to pour a slab foundation and the key factors that influence the concrete’s final thickness.

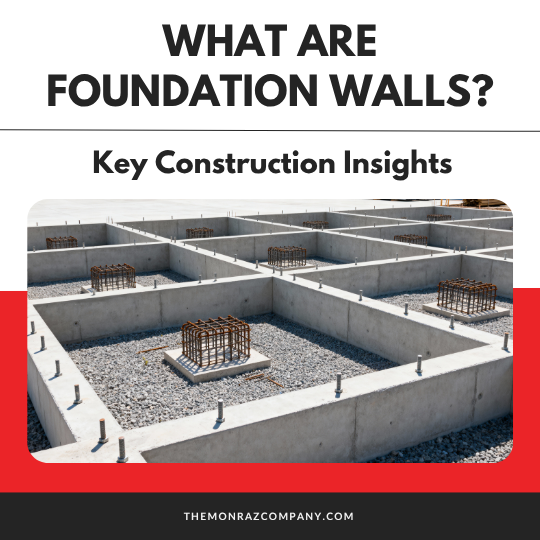

What Is a Concrete Slab Foundation?

A concrete slab foundation is a flat, reinforced layer of concrete poured directly on the ground to support a building’s weight. Since it’s placed directly on the ground, it’s also commonly called “slab on grade.” It acts as both the structural floor and the foundation system, transferring loads into the soil below.

Slab foundations are widely used in commercial, industrial, and residential construction because they’re strong, durable, and cost-efficient. This makes them ideal for supporting heavy traffic, equipment, and long-term building performance.

How Thick Should a Concrete Slab Foundation Be?

The thickness of a concrete slab foundation depends on many factors. However, we can provide the average depth for each type of property:

- Residential: 4 to 6 inches thick

- Commercial: 6 to 8 inches thick

- Industrial: 8 to 12 inches thick

- High-Load: 12 inches or thicker

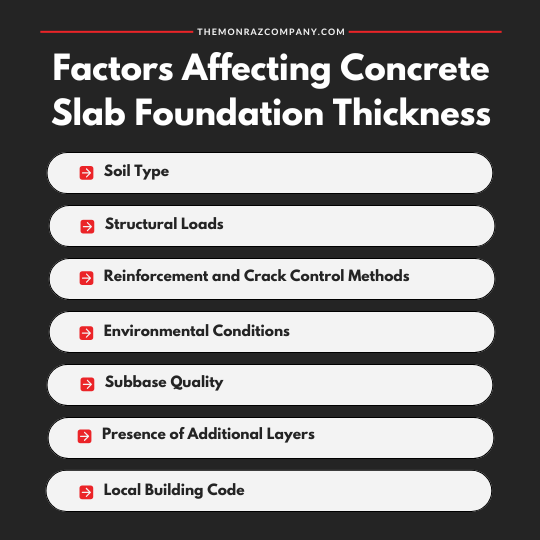

Factors Affecting Concrete Slab Foundation Thickness

Soil Type

Soil type is one of the main factors that dictate the required slab thickness. Ultimately, different types of soil offer different strengths, moisture retention, and stability. As a result, they also have different bearing capacities. Understanding how the soil behaves under load helps engineers determine the safest and most efficient slab depth for the structure.

For example, expansive clay soils often need thicker slabs or reinforced systems to prevent movement as the soil swells and shrinks. Weak or loose soils may also require thicker sections and

soil-cement stabilization to safely support the building’s weight. On the other hand, high-bearing soils provide stronger support, allowing contractors to use thinner slabs.

Structural Loads

Another important factor when determining slab thickness is the projected weight of the complete structure. Residential properties typically use 4 to 6-inch slabs, while commercial buildings often require 6 to 12-inch foundations.

This includes warehouses, industrial floors, distribution centers, agricultural buildings, and manufacturing facilities. Non-residential properties may also need additional thickness to handle concentrated loads such as heavy machinery, equipment pads, or pallet racks.

Reinforcement and Crack Control Methods

As concrete cures, it naturally shrinks. Without proper planning, that shrinkage can lead to unwanted cracking. To manage this, contractors use different crack control methods. Saw-cut joints create intentional weak points that guide where cracks form, and the spacing and depth of these joints often influence the slab thickness. Here’s more on why concrete cracks.

Another common approach is reinforcing the slab with rebar or welded wire mesh. Heavier reinforcement usually requires more depth so the concrete can fully cover and protect the steel. In some projects, contractors use post-tensioned steel cables instead, which strengthen the slab through internal tension. This method can allow for thinner sections, but it requires specialized load engineering to determine the appropriate thickness.

Environmental Conditions

More extreme climates often require stronger, thicker slabs. Areas with consistent freeze-thaw cycles and frost typically need deeper foundations and frost-protected footings to prevent heaving.

In contrast, hot climates, like those in Southern California, still require thicker slabs to limit shrinkage cracking and thermal movement. Properties in regions with mild, stable temperatures may be able to use thinner slabs, since the climate places fewer stresses on the concrete.

For more information, review “Can You Pour

Cement in Cold Weather?”

Subbase Quality

Gravel sits below a foundation as the subbase. If the gravel is loosely compacted or exceptionally thin, contractors will need more concrete to prevent settlement and cracking. However, a well-compacted granular base can adequately support a structure with a thinner slab. It also reduces long-term movement.

Presence of Additional Layers

Contractors often add additional moisture-protection layers to properties with a high water table or particularly wet climates. These additional layers require a greater slab depth to properly contain all materials. Vapor barriers, rigid insulation boards, and radiant heating systems all need adequate cover, increasing the thickness of the final product.

Local Building Code

Municipalities establish minimum slab and foundation thickness requirements in their local building codes to ensure structures remain safe and durable under regional conditions. These codes establish the baseline. However, contractors often increase the thickness based on soil, load demands, climate, and other factors outlined in this guide.

Prior to determining slab depth, research building codes regarding:

- Minimum thickness requirements for residential and commercial slabs

- Reinforcement rules, such as minimum rebar size, spacing, or wire mesh

- Subgrade and subbase preparation standards that indirectly affect slab performance

- Moisture protection requirements, especially in areas prone to vapor intrusion

- Inspection requirements to ensure thickness and reinforcement match plans

For Southern California standards, read California Building Code, Title 24, Part 2 (Volumes 1 & 2.)

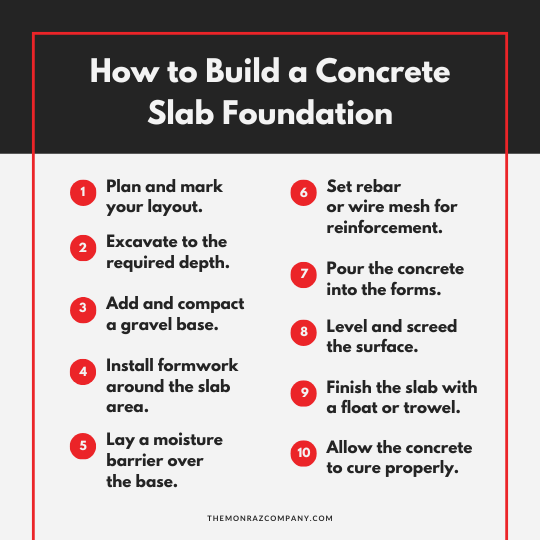

How to Build a Concrete Slab Foundation

Step One: Plan and mark your layout.

First, determine the exact size, location, and shape of the slab. Then use stakes, spray paint, string lines, and chalk to mark and outline the foundation. This step is essential, as it ensures the slab aligns with the building plans. Additionally, it should also confirm that the slab avoids property lines, easements, and existing utilities.

Step Two: Excavate to the required depth.

Now excavate the marked area and remove soil to the required depth, accounting for both the slab thickness and the gravel subbase. Use excavators, backhoe loaders, or skid steers to complete the bulk excavation.

After that, level and compact the exposed soil with a plate tamper, roller, or compactor. The base must be firm, even, and free of loose or disturbed soil before you move to the next step.

For additional information on necessary equipment, read our post titled:

Tools for Concrete:

Essential Equipment for Concrete Projects.

Step Three: Add and compact a gravel base.

To create the gravel subbase, spread a layer of crushed rock or gravel evenly across the excavated area. Use a plate tamper or compactor to densify the gravel until it reaches the required level of compaction. This layer is essential because it promotes proper drainage, reduces settling, minimizes cracking, and provides a stable, uniform surface for the foundation.

Step Four: Install formwork around the slab area.

Set up wooden or metal forms along the edges of the slab. Ensure they are level, square, and securely braced, because the forms will hold the poured concrete in straight, accurate boundaries. Any shifting during the pour can change the slab thickness and compromise the final finish.

Step Five: Lay a moisture barrier over the base.

Lay a heavy-duty plastic vapor barrier (typically 6 to 10 mil) across the compacted gravel. Overlap each seam by at least 6 inches and tape them securely. This barrier prevents ground moisture from migrating into the concrete and helps protect interior finishes from future damage.

Step Six: Set rebar or wire mesh for reinforcement.

Install rebar grids, wire mesh, or post-tensioning systems according to the engineering plans. Use chairs or supports to lift the reinforcement off the ground so it sits at the proper height within the slab. These reinforcement systems increase load-carrying capacity by adding strength and reducing the risk of cracking.

Step Seven: Pour the concrete into the forms.

Pour the concrete using a chute or pump truck, evenly distributing it throughout the formwork. Avoid dumping large amounts into one spot, as it could cause ingredient segregation. As soon as the concrete is placed, use shovels or rakes to move it into corners and around all installed reinforcement to ensure complete coverage.

Step Eight: Level and screed the surface.

Use a straight board or mechanical screed to strike off the excess concrete, bringing the surface to the proper grade. This step ensures the slab is even, level, and at the correct thickness. Proper screeding sets the foundation for a smooth finish.

Step Nine: Finish the slab with a float or trowel.

After screeding the concrete, use a bull float, hand float, or a power trowel to smooth and tighten the surface. This removes surface flaws and compacts the top layer, creating a durable finish that withstands heavy equipment and frequent traffic. For industrial floors, you’ll need to take extra time to achieve a tighter, more uniform finish. The surface should meet flatness and levelness requirements (FF/LL) and ensure long-term durability.

Step Ten: Allow the concrete to cure properly.

Curing is essential for achieving full strength and preventing cracking. Keep the slab moist or covered for several days using curing blankets, plastic sheeting, or curing compounds. Additionally, avoid heavy loads until the concrete reaches its specified strength, typically after 7–28 days.

The length of a cure can also be affected by the weather. Ensure you pour your slab during

pavement season, or take special precautions when

pouring cement in low or high temperatures.

For another method, read our guide to

dry pouring concrete slabs.

The thickness of a concrete slab depends on several factors.

Every successful project rests on a foundation built to the correct depth. The right slab depth protects the structure from unnecessary movement, stress, and long-term damage. Because of this, foundation thickness is not something you should estimate—it requires a professional’s trained eye.

If you want a precise and dependable build,

contact

TMC Engineering. Our team will evaluate your property, determine the correct slab depth, and handle your foundation project from start to finish with the expertise it deserves.

For more on concrete foundations, read these posts next: