Asphalt Overlay vs Replacement

When making decisions about upgrading asphalt surfaces, owners often face a choice between performing an asphalt overlay or pursuing a full replacement of the existing pavement. Both approaches aim to extend the lifespan of structures like driving and parking areas, however, each option has distinct advantages depending on the circumstances.

As contractors with years of experience in asphalt construction, we have worked on many resurfacing and replacement projects. Through these, we’ve seen how the condition of the underlying asphalt and the needs of the property often determine which path is preferred. With numerous factors to consider, selecting the right solution can sometimes be challenging.

Today, we want to provide clarity on the differences between these two common asphalt paving techniques. By understanding asphalt overlays versus full replacements, property owners and facility managers can make well-informed choices tailored to their situation!

Let’s explore the distinctive aspects of each approach so you know what questions to ask when considering repaving your parking lots, roads, or other asphalt surfaces!

Asphalt Overlay vs Replacement

What is Asphalt Overlay?

Asphalt overlay , also called asphalt resurfacing, involves laying a new layer of asphalt over the existing surface. This can be a very cost-efficient repaving option when the underlying asphalt remains structurally sound but shows signs of wear like cracking, rutting, or raveling.

Rather than removing and replacing all layers, an overlay preserves the existing base layers while providing a fresh driving surface. This makes it a quicker and less expensive alternative to full reconstruction as there is no demolition or disposal of the old pavement required.

Good candidates for overlays are roads and lots with aging asphalt that has lasted 5-10 years with light-to-medium traffic volumes. The existing pavement only needs to retain enough integrity to support the weight of additional asphalt and daily use.

When performing an overlay, contractors will first clean and repair any problem areas like large cracks. They will also check that the surface properly drains water and is generally in stable condition. Then, a fresh 1-2 inch layer of hot asphalt mix is uniformly applied and compacted over the treated surface.

Proper site preparation and installation are crucial; the new overlay must fully bond with the old pavement to prevent future debonding or cracking issues down the line!

What is Asphalt Replacement?

Asphalt replacement involves completely removing the existing asphalt pavement and underlying base materials, then rebuilding with new asphalt layers. This full-depth reconstruction is necessary when the pavement has deteriorated beyond the point of an economical overlay or repair.

Asphalt removal and replacement are necessary when the existing pavement has deteriorated too much to function as a suitable base. Common signs that replacement may be needed include extensive cracking throughout, deep rutting, potholes, distortion, or if the asphalt is excessively old (15+ years). The underlying base may also be compromised, resulting in uneven settling.

Higher traffic areas that undergo consistent heavy loads or experience harsh winter weather are more prone to reaching this state of disrepair sooner. Parking areas near building entrances also tend to deteriorate quickly due to frequent turning and braking.

When replacing asphalt, contractors will excavate down to the soil subgrade. They’ll inspect this layer to ensure it can sufficiently support new pavement without settling. The base is rebuilt using fresh aggregate material in lifts, followed by asphalt layers that are thoroughly compacted.

Replacement should be considered if an overlay patchwork becomes unsustainable. It provides the strongest foundation for a project designed to last another 10-20 years under heavy commercial or high-traffic conditions!

Asphalt Overlay vs Replacement Cost

The costs associated with an asphalt overlay versus full replacement can vary depending on the size and scope of the project. However, in general:

Asphalt Overlay : This is usually the most affordable resurfacing solution as fewer tons of asphalt mix are required compared to full-depth repairs. Just the material and labor to lay, grade, and compact a new wearing surface over intact pavement ranges from $3-6 per sq. ft., on average.

Asphalt Replacement : Full reconstruction demands much more labor, equipment, and asphalt materials to remove and replace all existing layers. Per-square-foot costs start around $5-10 due to added excavation, disposal of old pavement, base preparation, and compaction of multiple lifts.

Other potential added costs for either method include:

- Surface repairs prior to resurfacing/replacement

- Patching holes and cracks

- Adjusting manhole and utility covers

- Applying sealcoats , tackle coats, or prime coats

- Striping and lane markings

For large commercial sites, a replacement project could cost several times more than even an extensive overlay. However, a full replacement ensures long-term structural integrity versus the maintenance need of overlays every 12-15 years. A proper cost-benefit analysis is essential!

Overall, overlays provide a cheaper way to restore drivability if the base is sound, while replacement yields greater longevity in heavily used areas with compromised foundations.

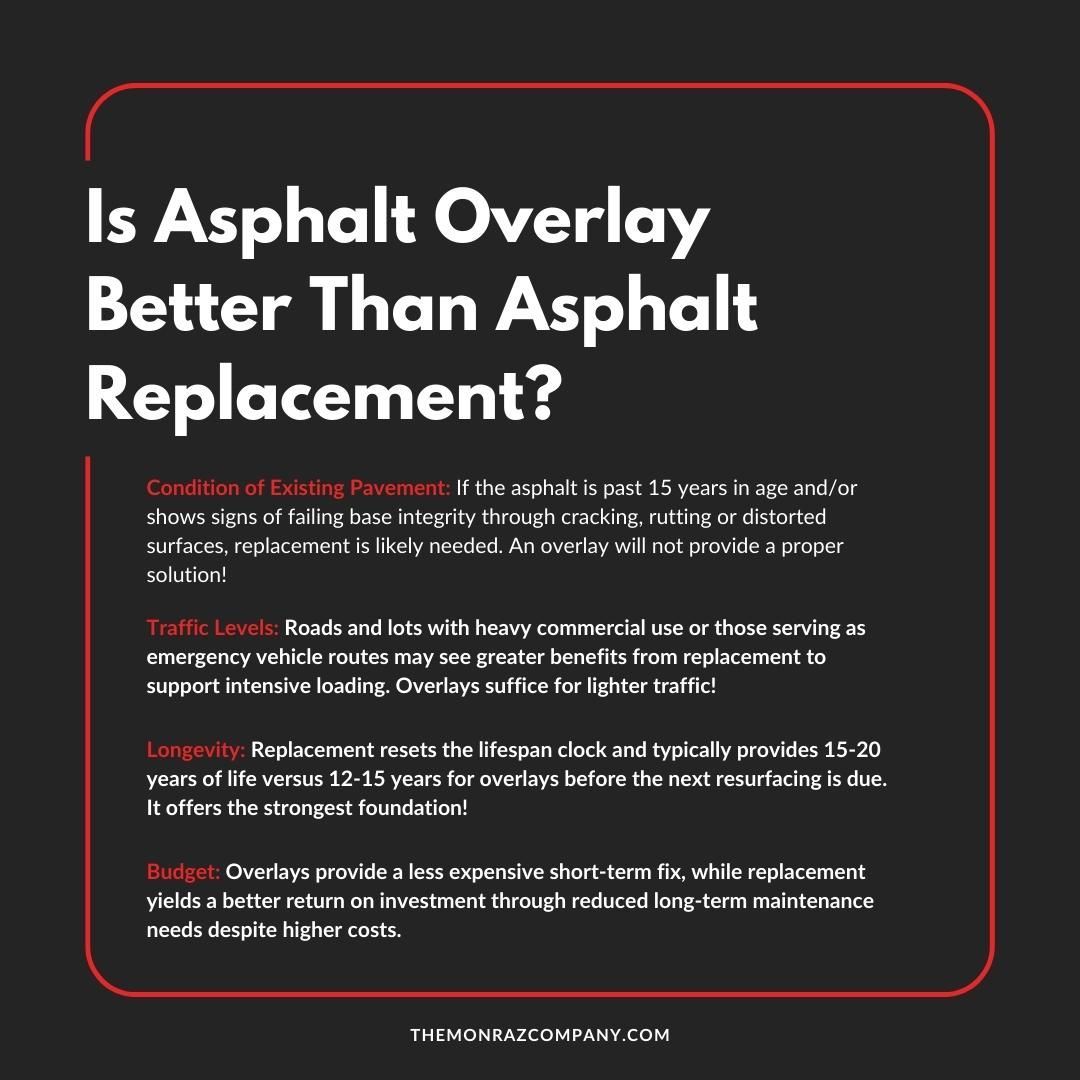

Is Asphalt Overlay Better Than Asphalt Replacement?

When deciding between these two repaving methods, there are some key factors to consider:

Condition of Existing Pavement : If the asphalt is past 15 years in age and/or shows signs of failing base integrity through cracking, rutting, or distorted surfaces, replacement is likely needed. An overlay will not provide a proper solution!

Traffic Levels : Roads and lots with heavy commercial use or those serving as emergency vehicle routes may see greater benefits from replacement to support intensive loading. Overlays suffice for lighter traffic!

Longevity : Replacement resets the lifespan clock and typically provides 15-20 years of life versus 12-15 years for overlays before the next resurfacing is due. It offers the strongest foundation!

Budget : Overlays provide a less expensive short-term fix, while replacement yields a better return on investment through reduced long-term maintenance needs despite higher costs.

In summary – overlays are a more affordable option when the existing asphalt is stable enough to support added layers without failure. However, replacement should be performed on heavily deteriorated pavements. Or those serving heavy industries to ensure optimum structural integrity for many years of service.

Proper evaluation of conditions is key to choosing the approach that best matches your project needs and budget.

Both asphalt overlay and complete replacement have their appropriate uses when it comes to repaving worn roadways, parking lots, and other surfaces. Choosing between the two options requires carefully assessing the condition of the underlying pavement. As well as factors like budget, intended lifespan, and traffic levels.

An overlay provides a cost-effective way to extend the life of asphalt. One that remains structurally sound but needs a fresh wearing surface. Replacement ensures optimal long-term performance by fully rebuilding from the base up when deterioration has rendered the existing layers unsuitable. By understanding the distinctive aspects of each approach, property owners and managers can make an informed decision tailored to their unique project requirements!

Contact us today so we can help evaluate your site conditions and recommend the most suitable solution. Our team of experienced paving professionals at TMC Engineering also provides a wide range of transportation construction services to meet all of your project needs. Whether you need asphalt paving, striping, sealing, or concrete work, we have the expertise and equipment to handle the job efficiently and cost-effectively. By combining extensive industry knowledge with high-quality materials and workmanship, we can deliver durable, long-lasting results!