What Is Hydraulic Cement? Fast, Water-Resistant Solutions

Concrete has been used for centuries to tackle projects both large and small. Over the past few hundred years, manufacturers have developed a variety of concrete types, each designed to suit specific project needs. Choosing the right materials can make all the difference in achieving a durable, cost-effective, and long-lasting result.

In this post, we’ll focus on a specialized type of concrete called hydraulic cement. If you own a commercial or industrial property, there’s a good chance you’ll encounter hydraulic cement in your concrete projects.

This is especially true if you have projects that require fast, water-resistant repairs. Understanding how hydraulic cement performs can clarify why it’s the preferred choice for many repair and restoration projects.

If you think your upcoming concrete project may require hydraulic cement or a contractor has suggested it, get expert

guidance from

TMC Engineering. Our trusted team is here to help Southern California property owners with reliable advice, quality service, and free quotes. Our goal is to ensure your project is completed correctly the first time, with the right materials and expert workmanship.

What Is Hydraulic Cement? Fast, Water-Resistant Solutions

Hydraulic cement is a special type of cement that can cure underwater or in any other damp conditions. Instead of needing to dry out like traditional cement, hydraulic cement hardens when it comes into contact with water. This process is called hydration. The finished product is fast-setting, water-resistant, durable, and versatile.

Type of Hydraulic Cement

- Type K (High-Strength, Fast-Setting Cement)

- Type S (Standard Hydraulic Cement)

- Type N (Non-Shrink/Expansive Cement)

- Type M (High Early Strength Cement)

- High Sulfate Resistant Hydraulic Cement

- Rapid-Setting Hydraulic Cement

- Underwater Hydraulic Cement

- Shrink-Resistant Hydraulic Cement

What Is in Hydraulic Cement?

- Portland Cement: Main binder, providing strength and durability

- Calcium Silicates (Alite and Belite): Reacts with water to form calcium silicate hydrate, providing the cement with additional strength

- Calcium Aluminates: Help the cement set quickly and improve water resistance

- Additives/Fillers: May include fine sand, limestone, or other minerals, sometimes incorporating expanding agents to help seal cracks

- Water: The chemical process that allows hydraulic cement to set and harden when it comes in contact with water

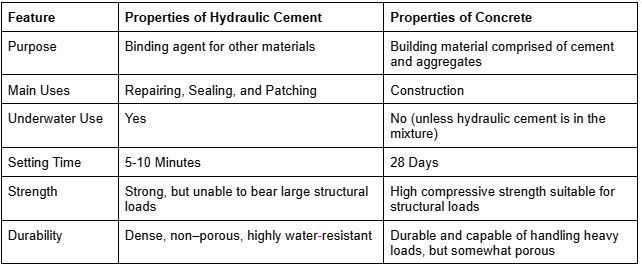

Hydraulic Cement vs. Concrete: Understand the Difference

Hydraulic cement and concrete might seem like the same product, but they are actually two different materials. Hydraulic cement is a binding agent, whereas concrete is a building material composed of cement and aggregates. Some concrete mixes even include hydraulic cement to enhance performance. There are also multiple types of hydraulic cement for additional specialization.

Here are the key differences:

Is Hydraulic Cement Necessary?

Hydraulic cement is essential for stopping active leaks and addressing moisture-related concrete issues. Unlike other materials, it can set and cure even when exposed to water, making it ideal for addressing pavement and foundation issues that involve moisture. Additionally, hydraulic cement offers a fast repair solution, curing in minutes rather than days. This is useful for property owners who need an expedited fix.

Hydraulic cement is unnecessary for

sealing cracks or

patching holes in normal or dry conditions, as there is no moisture. Contractors also typically avoid using it for large-scale pours, such as foundation cracks, slabs, or walls. Its rapid-setting nature can make it difficult to work with in extensive or complex projects. Therefore, while it is a valuable material in commercial construction, it isn’t suitable in every circumstance.

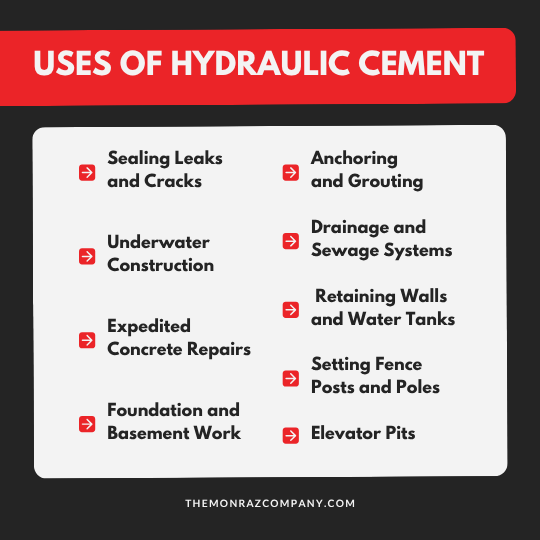

Uses of Hydraulic Cement

Sealing Leaks and Cracks

One of the most common uses of hydraulic cement is stopping water leaks. It is often applied to concrete walls, floor tanks, or foundations to seal any moisture and prevent further water infiltration. This watertight seal ensures the crack is completely filled, bonding with the existing material.

Here’s additional information on

how to repair

concrete foundations.

Underwater Construction

Underwater structures such as dams, bridges, tunnels, and marine constructions often use hydraulic cement. It sets and hardens even in wet conditions, creating a strong, durable bond that resists water.

Expedited Concrete Repairs

There are times when property owners cannot wait weeks for a patched area of concrete to fully cure. In these circumstances, contractors use hydraulic cement to provide the fastest repair possible. This allows traffic to continue much faster than traditional crack, pothole, or other structural repairs.

To learn more, visit: “What Causes

Potholes in the Road?” and “What Are the Causes of Potholes in Roads and Parking Lots?”

Foundation and Basement Work

Hydraulic cement is used to seal joints, holes, and cracks in foundation walls. Its fast-setting, water-resistant formula prevents moisture from infiltrating, protecting buildings from leaks, structural damage, or mold growth. This makes an ideal solution for both routine maintenance and emergency repairs.

Anchoring and Grouting

Hydraulic cement is ideal for anchoring and grouting because it sets quickly and hardens even in damp conditions. Its slight expansion fills gaps tightly, creating a strong, secure bond. This makes it perfect for setting anchor bolts, posts, machinery bases, concrete, and masonry that requires stability and load support.

Drainage and Sewage Systems

Water resistance is essential in manholes, pipes, and drainage systems, where constant exposure to moisture can cause structural damage. For these applications, contractors rely on hydraulic cement. Its fast-setting, water-repellent properties provide a durable seal, maintaining the integrity and longevity of these systems.

Retaining Walls and Water Tanks

Contractors use hydraulic cement in the construction of retaining walls and water tanks because it provides both structural strength and waterproofing. It’s ideal for retaining walls, swimming pools, cisterns, and reservoirs. These structures rely on strong, watertight, long-lasting solutions—even under constant exposure to moisture.

Setting Fence Posts and Poles

Hydraulic cement’s fast-setting properties make it an excellent choice for installing fence posts, poles, and other upright surfaces. It allows contractors to secure posts quickly and efficiently, minimizing downtime and eliminating long curing periods. Additionally, business owners then have the peace of mind that these structures will withstand constant exposure to the elements.

Elevator Pits

Hydraulic cement is commonly used in elevator pits to seal leaks, as it prevents water from compromising the structure. Without its water-resistant properties, these areas would be prone to damage, corrosion, and costly repairs over time.

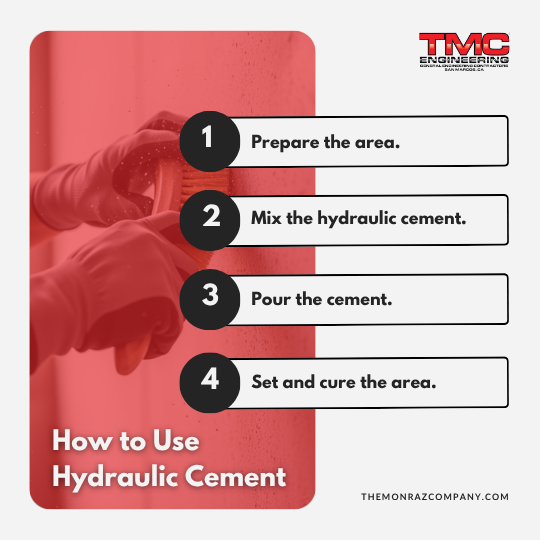

How to Use Hydraulic Cement

Step One: Prepare the area.

First, remove any dirt, oil, grease, or loose concrete from the area. Next, use a chisel or hammer to open up cracks or holes into a V-shape. This funnel shape helps the hydraulic cement bond optimally. Finally, dampen the surface with water, being careful to avoid standing water.

Step Two: Mix the hydraulic cement.

After preparing the area, mix the cement according to the manufacturer’s instructions. Typically, this means combining 4 parts cement with 1 part cold water. Using cold water slightly slows the setting time, giving you extra flexibility to work with it. Mix thoroughly until you achieve a thick, putty-like consistency that’s easy to handle.

Step Three: Apply the cement.

Once mixed, quickly press the cement firmly into the crack, hole, or joint using a gloved hand or trowel. Make sure it fills the space completely. Then, apply steady pressure and smooth the surface for 2–3 minutes until it begins to harden.

Step Four: Set and cure the area.

Finally, let the hydraulic cement sit for 5–10 minutes to fully cure. For optimal results, lightly mist the area for 24 hours after application to maintain moisture.

Hydraulic cement is a concrete mixture specialized for wet conditions.

Hydraulic cement is essential for addressing situations where moisture or water could compromise a structure. Its ability to set quickly, minimize curing times, and form a durable-water resistant bond makes it a reliable choice for cracks, repairs, and applications that other materials can’t handle.

If moisture is a concern in your upcoming Southern California concrete repair, contact

TMC Engineering. We provide expert solutions for water-related services and repairs. Additionally, if you’re requiring fast repairs to your surface, hydraulic cement and TMC Engineering are the combination you need for success.

For more on concrete repair, read these posts next: