Best Paint for Concrete Driveway: Contractor-Approved Solutions

Best Paint for Concrete Driveway: Contractor-Approved Solutions

Concrete driveways are incredibly common on commercial and industrial properties. They provide a durable, long-lasting parking and driving surface that withstands weather exposure, heavy vehicle loads, and daily traffic demands. However, despite all of its benefits, concrete can lose curb appeal, traction, and surface protection over time.

Painting the concrete surface is one of the most effective ways to achieve a cost-effective visual refresh. Additionally, concrete painting or coating adds a protective layer, forming a barrier that shields the surface from harsh external factors.

Ultimately, the materials selected will significantly influence the final results. Therefore, in this post, we will identify the correct product for the job and explain how to properly paint a concrete driveway.

Although concrete painting can be completed as a DIY project, working with professional contractors often delivers a higher return on investment. With experienced experts like the team at TMC Engineering, completed projects achieve stronger performance and more consistent aesthetic results. If you are located in Southern California,

contact us for more information.

Best Paint for Concrete Driveway: Contractor-Approved Solutions

There are a variety of reasons to consider painting a driveway if you’re a commercial or industrial property owner. Below are some of the key benefits of painting or coating a concrete surface:

- Enhanced curb appeal for tenants and customers

- Defined traffic flow through intentional color layout

- Improved traction on high-traffic or sloped driveways

- Reduced moisture intrusion, oil absorption, and surface wear

- Consistent appearance across multiple drive lanes, access points, or buildings

If you’ve determined that painting your concrete driveway will be advantageous to your property, continue reading to understand the necessary steps and products.

Can You Paint a Concrete Driveway?

Yes, you can paint a concrete floor or driveway with the right products. You would not use a standard exterior water-based or latex paint. Instead, you need an interior/exterior paint or coating formulated to withstand vehicle traffic, weather exposure, and temperature changes. Driveway paint penetrates the concrete surface and bonds to the substrate, allowing it to withstand heavy use. However, there are several types of concrete paint, which we will discuss further below.

Beyond product selection, the success of painting a concrete driveway depends on proper surface preparation and the concrete’s overall condition. The surface must be clean, dry, and structurally sound to allow proper adhesion and long-term performance. Additionally, contractors must address cracks, spalling, moisture intrusion, and surface contamination before painting or coating application.

If your surface has significant damage, it’s important to first understand the source of the problem. Reviewing our post “Why Does Concrete Crack?” can help you identify the root causes and address them properly for the best results after painting.

How to Paint Concrete Driveways

Step 1: Evaluate the condition of the concrete.

For concrete driveways to bond properly with paint, the concrete must be in optimal condition. Painting primarily has aesthetic benefits; it does not repair underlying issues. This means that before starting concrete painting preparation, you must thoroughly examine the surface condition.

Here are some common problems that will warrant repair prior to painting:

- Structural cracks or widening fractures

- Spalling, scaling, or flaking of concrete surfaces

- Areas with exposed aggregate or surface delamination

- Uneven sections caused by settling or movement

- Persistent moisture intrusion or drainage issues

- Efflorescence or moisture staining on the surface

- Oil-saturated or chemically contaminated areas

Step 2: Make necessary repairs and allow it to fully cure.

Once all preexisting issues have been identified, complete all necessary repairs. Concrete paint relies on a stable, intact surface to deliver the best results. First, address any persistent moisture or drainage issues. Next, repair structural cracks, widening fractures, and uneven sections. Finally, fix spalling, scaling, flaking, exposed aggregate, or surface delamination.

To complete these repairs, we recommend working with a professional contractor. If you have the proper concrete tools and experience to perform the repairs yourself, use the following resources to achieve the best results:

Step 3: Remove stains and clean the surface thoroughly.

You must thoroughly clean your concrete surface prior to painting. Begin by removing any efflorescence or moisture staining. Next, clean the oil and chemical contamination from the driveway. These deposits can create a barrier between the concrete and the paint, preventing proper adhesion. Here’s how to get oil stains out of cement and how to remove tar from concrete.

Once stains have been removed, thoroughly clean the rest of the surface. Sweep the area to remove dirt, dust, leaves, and gravel. After the surface is free of debris, pressure-wash the entire area to remove embedded dirt, mold, and any remaining surface contaminants. Once cleaning is complete, allow 24 to 48 hours of drying time before painting.

Step 3B: Etch or profile the concrete. (If needed.)

Paint requires a porous concrete surface to bond properly. Over time, concrete surfaces can wear down, becoming smooth, hard-troweled, and dense. This makes the concrete slick and prevents proper water absorption. If this is the case, the surface will need to be etched or mechanically profiled to allow the paint to bond.

To etch the concrete, prepare a concrete etching solution and apply it using a sprayer. Scrub the solution into the surface with a stiff-bristle brush—the solution will foam as it reacts with the concrete. Then, allow it to sit for the manufacturer’s recommended amount of time. Rinse the surface thoroughly once the process is complete.

Mechanical profiling is used in more difficult situations. This method involves using a diamond grinder, surface grinder, or shot blaster to grind the surface to a consistent texture. After grinding, the surface must be thoroughly vacuumed and cleaned before painting.

Step 4: Apply concrete primer.

A primer helps create a stronger bond between the concrete and the paint or coating. This step is essential as driveways experience frequent vehicle traffic. Apply the primer evenly and in thin layers using a roller, sprayer, or brush according to the manufacturer’s instructions. Then, allow the primer to fully dry and cure before painting. While the surface may feel dried to the touch within a few hours, a full cure can take 24 hours or more.

Step 5: Paint the surface with specialty coating or paint.

Once the primer has fully cured, the surface is ready for paint or coating. Use a specialty concrete paint or coating and apply it in thin, even coats. The manufacturer’s instructions will specify the appropriate application method, whether that is a roller, sprayer, or brush.

Allow each coat to dry within the recommended recoat window before applying the next. Avoid applying paint in extreme temperatures or wet conditions, as this can affect adhesion and curing.

Step 6: Allow proper curing time.

After painting is complete, the concrete surface must fully cure before being put back into service. Like the primer, the paint will feel dry to the touch within 4 to 8 hours. However, the complete curing process takes much longer and is primarily to achieve your paint’s appropriate hardness and durability.

Most concrete driveway paints and coatings require 24 to 72 hours before light foot traffic is allowed and 3 to 7 days before vehicle traffic can resume. However, cure times vary based on the product used, temperature, humidity, and airflow. Placing traffic on the surface too soon can result in tire marks, peeling, or premature coating failure.

Step 7: Seal for added protection and durability.

Sealers are UV-resistant and help protect against moisture intrusion, oil and chemical exposure, surface wear from vehicle traffic, and sun damage. Therefore, applying a concrete sealer over the painted surface provides an additional layer of protection and helps extend the life of the coating.

Before sealing, confirm the paint or coating is completely dry and cured according to the manufacturer’s guidelines. Apply the sealer evenly using a roller or sprayer, following recommended coverage rates. Thin, uniform coats provide the best performance and reduce the risk of peeling or clouding.

Once applied, allow the sealer to cure fully before allowing traffic on the surface. It’s important to note that contractors aren’t required to seal every product. However, when it is compatible with the chosen material, it can significantly improve durability and long-term performance on commercial and industrial driveways.

For more guidance, read our article titled “Can You Seal Coat an Old Driveway?” Additionally, select one of these

top-rated concrete sealers for the job.

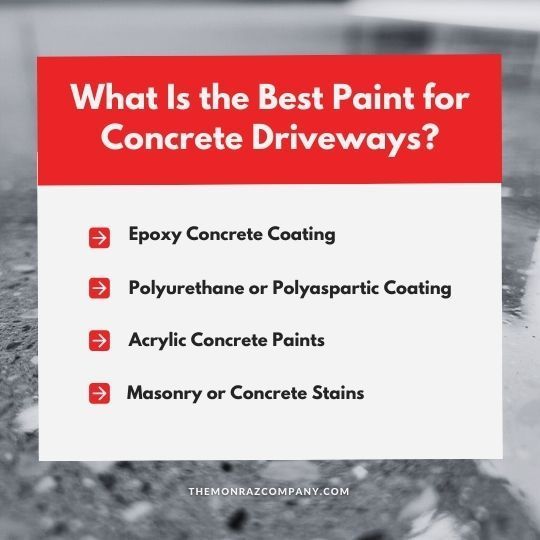

What Is the Best Paint for Concrete Driveways?

Epoxy Concrete Coating

- Product: Two-part epoxy-based concrete coating

- Uses: Commercial garages, industrial floors, and some low-traffic driveways

- Pros:

- Extremely durable and abrasion-resistant

- Strong adhesion to properly prepared concrete

- Creates a thick, protective surface layer

- Cons:

- Not UV resistant and can yellow or chalk in sunlight

- Less flexible and prone to cracking with slab movement

- Requires precise surface prep and mixing

- Commonly marketed as floor paints, but not always rated for outdoor driveway exposure.

Polyurethane or Polyaspartic Coating

- Product: High-performance resin-based concrete coatings

- Uses: Commercial driveways, industrial access lanes, and high-traffic areas.

- Pros:

- Highly UV-resistant and color-stable

- More flexible than epoxy

- Excellent resistance to chemicals and moisture

- Faster cure times in many formulations

- Cons:

- Higher material and installation costs

- Short working time can make DIY application difficult

- Often requires professional installation

Acrylic Concrete Paints

- Product: Water-based or solvent-based acrylic paint designed for concrete

- Uses: Light-duty commercial driveways and decorative applications

- Pros:

- Easy to apply and widely available

- More breathable than epoxy-based systems

- Cost-effective for visual refreshes

- Wide range of available paint colors

- Cons:

- Less durable under heavy vehicle traffic

- Shorter lifespan compared to coatings

- Requires more frequent maintenance or reapplication

Masonry or Concrete Stains

- Product: Penetrating acid-based or water-based concrete stains

- Uses: Decorative driveways and architectural concrete surfaces

- Pros:

- Penetrates the concrete rather than forming a surface film

- Will not peel or flake

- Creates a natural, variegated appearance

- Cons:

- Does not provide surface protection on its own

- Limited color consistency and coverage

- Requires sealing for durability and stain resistance

While this is not a true concrete paint, it can offer similar results. Learn more about stained concrete driveways here.

You can effectively paint concrete driveways to provide added protection and curb appeal.

For commercial and industrial properties, selecting the right products and applying them correctly is essential for long-term performance. Factors like traffic volume, exposure conditions, and surface condition all play a role in how well a painted driveway will hold up over time.

If your property is in Southern California, contact TMC Engineering to evaluate your concrete driveway. Moreover, our team of experts can recommend a coating solution designed for durability, safety, and consistent results.