Can You Sealcoat in the Rain?

Sealcoating is a process that involves applying an additional layer on top of asphalt-based pavements and driveways. This layer acts as a protective shield, safeguarding the asphalt from the elements and other potentially damaging circumstances.

By employing asphalt seal coating, property owners can significantly extend the life of their pavements and driveways. A high-quality seal coat will protect asphalt from weather elements, oxidation , and daily wear and tear. Though the longevity of your seal coat is somewhat dependent on factors like climate, traffic, and maintenance, a seal coating can help keep your asphalt pavement in optimal condition for as long as possible.

With seal coating being such an essential piece of asphalt maintenance, getting the process underway is of the highest importance. However, if you’re seal coating during a potentially rainy season, you need to have a plan for responding to less-than-favorable weather conditions. So, today, we’ll be exploring the question: “Can you seal coat in the rain?”

However, if you want a quick answer to your Southern California asphalt project questions, call the professionals at TMC Engineering, get your answer, and a FREE QUOTE!

Can You Sealcoat in the Rain?

It’s not recommended that you sealcoat when it’s raining or when there is even rain in the forecast. If seal coating is done in the rain, you’ll not get optimal results and the seal coating could essentially fail to act as a protective layer, rendering the process ultimately pointless.

Asphalt emulsion sealers are water-based coatings that require time to fully dry and cure after application. There are several ways by which rain can interfere with this critical drying and curing process. Firstly, any rain that lands on a sealed driveway while the sealer is still wet could dilute and wash away the sealcoat solution. This undermines the purpose of your seal coating and wastes much of the product purchased. Your coating will, of course, not have the durability or protective quality you were aiming for if you seal coat in the rain.

Additionally, when rain falls on a sealed pavement before its cure time is over, excess moisture can be trapped under the sealer. This prolongs drying to the point where the coating doesn’t cure and harden properly. The result of this incomplete curing process is premature cracking and ultimately loss of adhesion over time. To put it simply, seal coating in the rain could shorten the lifespan of the asphalt instead of lengthening it.

Why Rain and Sealcoating Don’t Mix

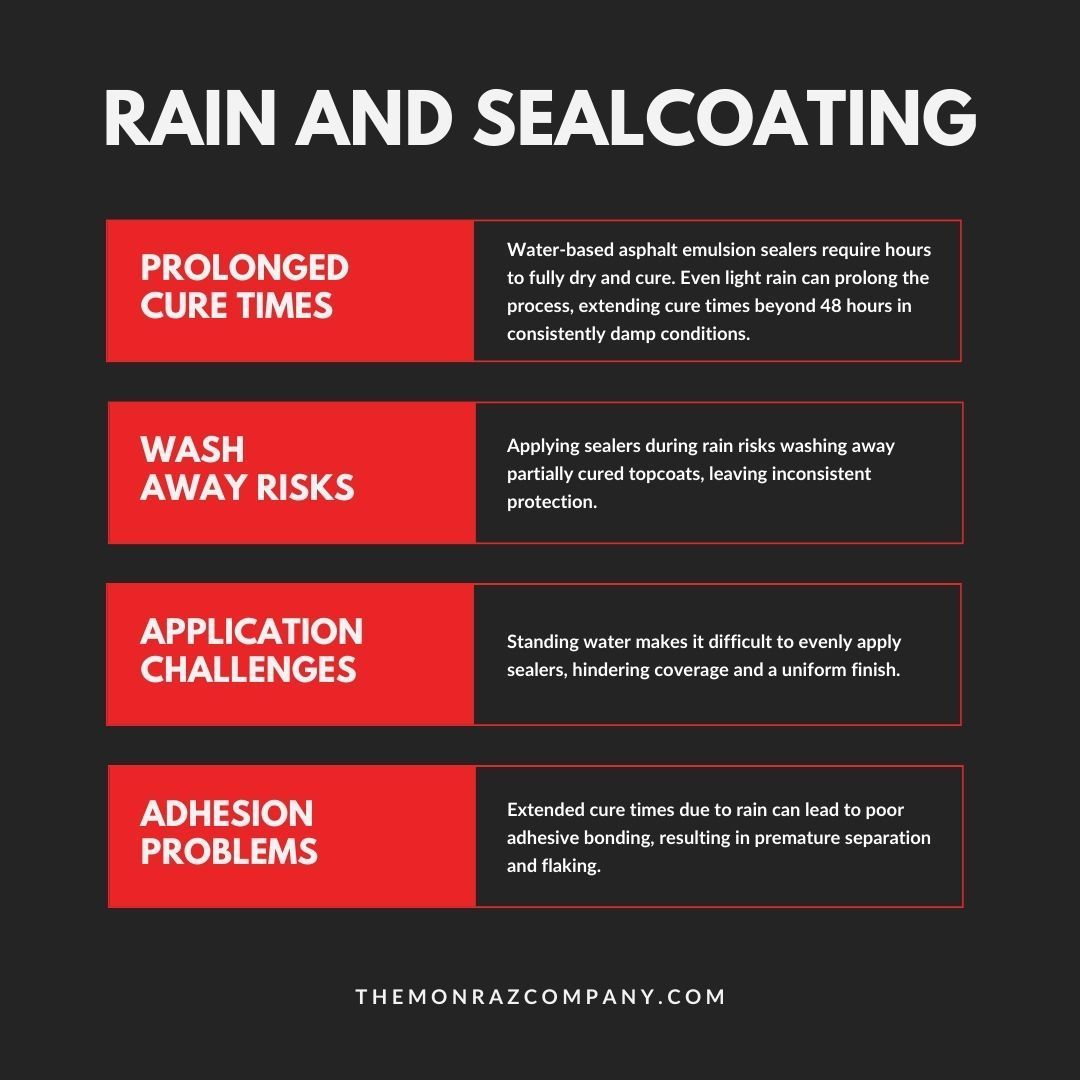

Prolonged Cure Times

As mentioned, asphalt emulsion sealers are water-based coatings that require hours to fully dry and cure. The lightest of rain showers can easily introduce excess moisture, slowing the evaporation of water from within the sealer mixture. This prolongs the critical window needed to fully harden into a durable protective film. Cure times may be extended to over 48 hours after application in consistently damp conditions, which is longer than the standard 24 hours or less in fair weather. This is a big problem if your commercial property needs to regain access to the asphalt surface as soon as possible.

Wash Away Risks

Applying sealers during steady rainfall puts you at serious risk of partially cured topcoats washing away from the sealed driveway long before the necessary bonds are able to form. Moving water will always displace the lightly attached emulsions if they’re still wet. This creates thin, inconsistent protective layers that fail to guard pavement from within.

Application Challenges

Surfaces that have standing water on them make for an unstable work site by making it difficult to uniformly distribute sealers via sprayers, brushes, or squeegees. Puddles can inhibit achieving recommended application rates, coverage, and finished appearance. It’ll be even more difficult in low-lying areas where the rain has collected in pools. All in all, the conditions will bring immense challenges for the commercial applicators.

Adhesion Problems

A long cure process can allow rain to soak into the asphalt under the sealcoat. This can interfere with the sealcoating bonding appropriately to the aged pavement surface. Without a strong bond, sealers face premature separation under winter weather conditions and traffic wear. Ultimately, this can lead to flaking and cracking soon after application.

Best Weather for Sealcoating

The ideal time to sealcoat an existing asphalt driveway or parking lot is during dry and mild weather conditions. The temperature should be consistently above 50 ° F for successful application , drying, and curing of the sealant. It is advisable to avoid sealcoating on days with temperature extremes , excessive wind, or high humidity , as all these conditions can impact the effectiveness of the sealcoat application.

Our best advice is to monitor the weather prior to scheduling the sealcoating and keep up with any updates on the forecast leading up to the application. To maximize the effectiveness of the sealcoating, also ensure that the asphalt surface is clean and free from debris, dirt, and oil.

Though the process of prepping asphalt for sealcoating and finding the right weather window for application may seem tedious, this is an essential process for prolonging the life of your asphalt!

We want you to get the most use out of your asphalt pavement investment, and premature removal and replacement is costly. So, join with experts like us to find the perfect time to sealcoat your asphalt and restore it for years of additional use!

Sealcoating is only beneficial when done the right way, at the right time, and under the right conditions.

Sealcoating is easily one the most important components of asphalt maintenance! It helps you protect your investment and extend the life of your asphalt driveway or parking lot. By creating a shield against UV rays, heavy traffic, extreme weather conditions, and other harmful events , sealcoating ensures your asphalt surface remains functional, durable , and visually appealing .

For best results, ensure you sealcoat in optimal weather conditions. You can find out more about asphalt installation, maintenance, and repair on our blog. But, if you’d rather not worry about the details and follow the weather forecast, let the professional handle the job! At TMC Engineering, we’ve got the expertise to handle any asphalt or concrete project needed on your commercial property. Contact us, and we’ll make sure you get the most out of your investment.

TMC is happy to do this for you! Just contact us for a free quote today.