How Long After Sealing Driveway Can You Drive On It?

Regularly sealcoating your driveway is a good way to ensure that your pavement remains durable and well-protected. Asphalt and concrete driveways must be maintained to withstand the wear and tear from regular traffic, UV rays, chemicals, water intrusion, and other environmental factors. Sealcoating gives you assurance of the longevity and strength of your driveway or pavement.

With this information, it’s clear that sealcoating is an essential part of asphalt and concrete maintenance . However, the process of sealcoating is not free of problems. The downtime required after application for drying and curing can disrupt your business or commercial property operations, costing you time and money.

So, today, we’ll discuss how low you’ll need to wait after a sealcoat before driving is safe again. This should help you better plan your project and avoid headaches caused by the duration of application, curing, and drying.

However, if you’d like a quick answer to your commercial sealcoating needs and you’re in Southern California, give us a call for a FREE QUOTE . We’re experts in all things concrete and asphalt installation, repair, and maintenance. Our expert staff will get you answers to your questions and help you schedule your first seal coat at just the right time!

How Long After Sealing Driveway Can You Drive On It?

It’s recommended that you wait 24-48 hours after sealer has been applied to drive or park on the pavement. This is to ensure proper curing takes place and the coating bonds properly to the existing material to ensure durability. Yes, it’ll take about 30 total days to complete curing, but driving is safe after a day or two. This is the recommendation under normal conditions to avoid potential wheel marks or damage to the uncured surface from early traffic.

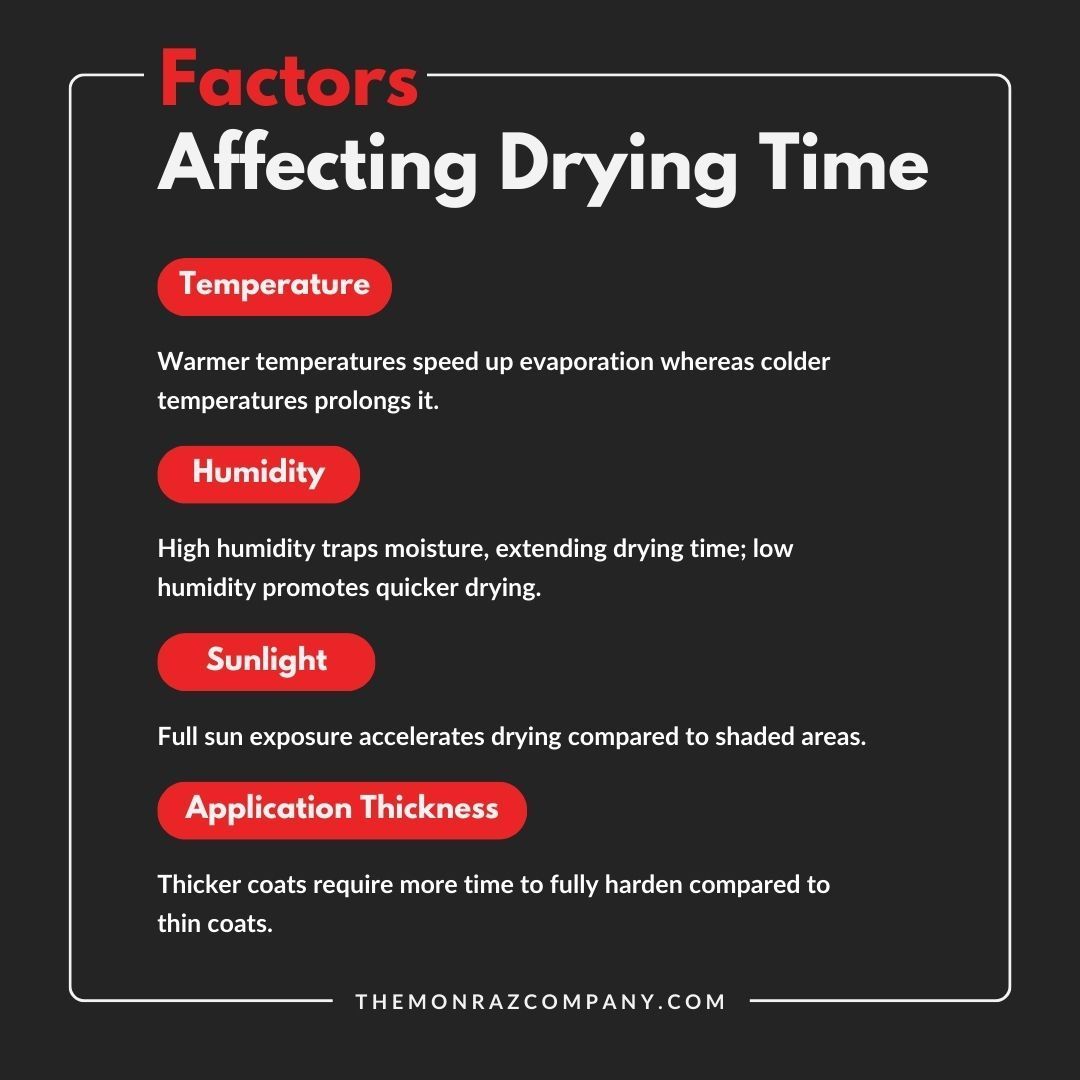

There are some other factors that can influence the length of sealcoat curing and drying. Weather conditions like temperature, humidity, and prevalence of sunlight can further extend the curing time . Discuss with your contractor the status of the process before allowing traffic, even if it’s been 38 hours.

Let’s take a closer look at how each of these factors can influence drying.

Factors That Influence Sealcoat Drying and Curing

Temperature

Warmer temperatures above 60° F promote faster evaporation , so you could see your sealcoat dry more quickly in this instance! Adversely, colder temperatures can prolong the drying process by allowing the pavement to retain moisture. It’s optimal to sealcoat during warm weather.

Humidity

High humidity is known to trap moisture under the sealer. This further lengthens cure times. Depending on the humidity and temperature, you could easily see drying and curing extended to up to 72 hours.

Sunlight

Full sun exposure speeds drying compared to shaded areas. This, again, has to do with evaporation! Light foot traffic is safe in such conditions even as early as after 24 hours.

Application Thickness

The type of coat used can also affect how long you’ll have to wait for a sealed driveway. A thicker layer of sealcoat will take longer to penetrate and harden.

How To Avoid Damaging Newly Sealed Driveway

Redirect parking.

Parked vehicles are some of the most common culprits of damage to newly sealed surfaces. Ensure that you provide your customers and/or employees alternative parking options that are clearly marked. Prematurely parked cars could leave indents or marks on the sealcoat and hinder the integrity of the pavement. Watch the weather.

Post-application conditions such as rain can threaten the durability and longevity effectiveness of your newly sealed driveway. Avoid this by checking forecasts regularly and make plans to protect your surface through adverse weather conditions if necessary.

Hire professional sealcoaters.

The best way to avoid damage to sealcoatings and reopen your parking lot faster is to hire professionals! Experienced applicators understand factors influencing localized cure times better and they know how to execute the project to avoid unnecessary problems. If you’re in Southern California, contact TMC Engineering and get your next sealcoat scheduled! We’ll take care of not only application, but we’ll help you find the perfect time to execute the process that minimizes downtime and headaches.

Under normal conditions, it’s best to stay off a freshly sealcoated parking lot for 24 to 48 hours.

When sealcoating is performed in optimal conditions, applying sealer only requires around 48 hours of restricted use of your pavement. The sealcoat will continue to bond over the next 30 days, strengthening the pavement. Use the tips above to target the best time to sealcoat for optimal results. And, of course, recommend staying off the driveway or parking lot until a professional has determined it’s safe to do so.

We hope this overview on how long to wait before driving on a newly sealed driveway proves useful in protecting your asphalt or concrete surface and the continued operations of your business. If you still need help, don’t hesitate to contact us for all your expert paving needs!

Here at TMC Engineering , we have a deep commitment to delivering projects executed using the highest standards for safety , workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further we’ve got all you need and more!