How to Strip Concrete Sealer: Expert Tips and Techniques

Concrete sealer stripping is one of the most labor-intensive jobs in commercial property maintenance. Yet, it becomes unavoidable when your current sealer deteriorates, becomes discolored, or hinders the adhesion of new coatings.

There are several reasons that may require you to strip concrete sealer from your California commercial property. Maybe your present sealer has a cloudy finish, or possibly you're preparing the surface for a new renovation. We’ve discussed

how to remove concrete sealer in the past and even

how to remove epoxy from concrete. But today, we’re discussing how to properly strip concrete sealer in commercial settings.

This detailed guide explains how to strip concrete sealer successfully with minimal disruption to your business activities. We will cover both solvent-based sealers and water-based sealers, as well as discuss how to know when stripping is necessary.

If you’d like a quicker or more specific answer to your concrete sealer stripping, the experts at

TMCEngineering would be happy to assist you. Our goal is to provide reliable, efficient solutions for all your commercial construction needs throughout Southern California. Our team of experts are ready to guide you through any and all concrete or asphalt needs.

How to Strip Concrete Sealer

Before starting any concrete sealer removal project, you need to know what type of sealer is currently protecting your surfaces. Two general categories dominate the commercial sealer market: solvent-based sealers and water-based sealers. Each has different removal methods and chemical strippers.

You can identify which type of sealer you’re dealing with through easy testing procedures. Begin by applying a small quantity of xylene or acetone to an inconspicuous section with a clean cloth. If the sealer softens or dissolves, then you have a solvent-based sealer. Water-based sealers are usually resistant to these solvents and need alternative identification procedures.

If you don’t have xylene or acetone, you can also apply water to the surface. If water beads up entirely, you probably have an acrylic component in your sealer. If water penetrates partially, you may have a water-based sealer that has deteriorated. The tests allow you to decide on the best removal method.

Knowing your sealer type saves time and money. Correct identification also allows you to choose compatible replacement sealers once you have finished the removal process. It is strongly advisable that you carry out these tests in several areas. This is because some properties have had different sealers applied to different sections over the years.

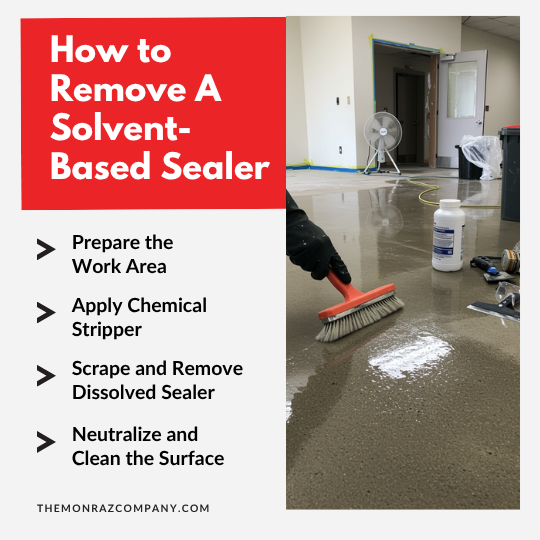

How to Remove a Solvent-Based Sealer

Solvent-based sealers typically react well to chemical strippers specifically formulated for solvent-based and acrylic coatings. The removal involves a systematic application and the use of appropriate safety precautions around your commercial premises. Here is our recommended method for effectively removing a solvent-based sealer:

Prepare the Work Area

Begin by moving all furniture, equipment, and any other items that may hinder the stripping process from the work area. Ventilation becomes highly important when using chemical strippers, particularly in closed spaces. That said, ensure you open all available windows and doors, and then position industrial fans to keep the air circulating.

Protect nearby surfaces that you don’t want exposed using painter’s tape and plastic sheeting. This prevents chemical damage to the decorative trim, fixtures, or walls. Also, ensure all electrical outlets and switches within the work area are well-protected from chemical splashing.

To prepare, gather the necessary property safety equipment, including chemical-resistant gloves, eye protection, and respirators rated for solvent vapors.

California

OSHA guidelines demand special safety practices when applying chemical strippers in a commercial setting.

Apply Chemical Stripper

Choose a chemical stripper fit for solvent-based sealers. Follow the manufacturer’s guidelines carefully, as the application method varies by product. Most commercial strippers need particular temperature ranges to work optimally.

Apply the stripper with a synthetic brush or roller in sections of about 100 square feet. This sectioning ensures that the stripper does not dry out before you have a chance to remove the dissolved sealer. Maintain consistent coverage, but avoid puddles that can damage the concrete substrate.

Allow the stripper to dissolve the sealer for about 15 to 30 minutes. You’ll notice the sealer begin to soften and lift from the concrete surface. Try not to walk on treated areas while waiting to avoid tracking chemicals around your facility.

Scrape and Remove Dissolved Sealer

Remove the softened sealer with plastic scrapers or putty knives. Metal tools are not advisable because they will scratch the concrete surfaces. Try to remove it methodically across each section.

For stubborn areas where the sealer is still bonded, reapply more stripper and provide additional dwell time. Some commercial sealers require several applications in order to fully remove them. Patience at this juncture will keep you from damaging the underlying concrete.

Collect all scraped material in appropriate disposal containers. California environmental regulations govern the disposal of chemical waste, including dissolved sealers and used strippers. Contact licensed waste disposal companies to ensure compliance with local and state requirements.

Neutralize and Clean the Surface

Following the removal of dissolved sealer, neutralize any residual chemical traces with clean water and suitable neutralizing agents. Some chemical strippers have special neutralization steps specified on their technical data sheets.

Rinse the whole area thoroughly with clean water, then use wet vacuums or squeegees to extract standing water. You may need to repeat this process several times to remove all chemical residues. To verify that complete neutralization has taken place, analyze the pH of the final rinse water.

Let the concrete surface dry thoroughly before evaluating the removal outcomes. Proper drying usually takes 24 to 48 hours, based on temperature and humidity levels. The drying time also indicates areas that might need further treatment.

How to Remove a Water-Based Sealer

Water-based sealers are more difficult to strip than solvent-based types. You typically remove them mechanically or with special strippers designed specifically for water-based coatings. Here is our recommended method for effectively removing a water-based sealer:

Evaluate Removal Method Options

Start by confirming whether your water-based sealer will react to chemical strippers or if it requires mechanical removal. Apply a small amount of water-based sealer stripper to test areas, following the manufacturer’s instructions.

If chemical stripping is not effective, mechanical methods will be required. These involve grinding, sanding, or pressure washing using suitable equipment. There are benefits and restrictions to the use of each of these mechanical methods in commercial properties.

Consider the condition of the concrete substrate when choosing your mechanical methods. Decorative concrete surfaces, such as

exposed aggregate

concrete, need less severe methods to maintain their aesthetic appeal. Typical industrial floors, on the other hand, are more tolerant of aggressive mechanical removal methods.

Chemical Stripping Process

Water-based sealer strippers work differently compared to solvent-based strippers, requiring longer contact time and repeated applications. Ensure you follow the manufacturer's application instructions and maintain proper ventilation throughout the process.

Water-based sealers tend to come off in sheets instead of completely dissolving. Scrape off lifted sections of sealer using plastic scrapers, moving evenly across the treated surface for optimal results.

Reapply the stripper on areas where the sealer is still bonded after the first treatment. For some water-based sealers, multiple applications may be necessary to remove them completely. This is common in high-traffic areas where the sealer has worn down into the pores of the concrete.

Mechanical Removal Methods

If chemical stripping does not remove the water-based sealer, opt for mechanical methods instead. Diamond grinding is the most effective method for large commercial areas, but it requires specialized equipment and experienced operators.

Floor sanders with aggressive grits can also strip thin applications of sealer from smooth concrete surfaces. Begin with coarser grits to strip most of the sealer, then move to finer grits to reach the intended surface profile.

Power washing with hot water and suitable detergents can also strip some water-based sealers. It is most effective on exterior surfaces where water runoff is less of an issue. Interior applications, on the other hand, require careful management of water and extended drying times to ensure proper results.

Surface Preparation Following Removal

After removal, thoroughly clean the concrete surface to get rid of all debris and dust. Vacuum up all loose material and mop with clean water to remove fine dust that may interfere with subsequent coatings.

Examine the concrete surface for any residue of the old sealer or any damage due resulting from the removal process. Also, ensure you address any surface defects before applying new sealers or coatings. This helps to achieve maximum performance from the follow-up surface treatments.

Allow adequate drying time before proceeding with any additional surface treatments. Mechanical removal methods, in particular, often open concrete pores, requiring longer drying periods than chemical stripping alone.

When to Strip Concrete Sealer

Sealer failure is the most typical cause for removal. Failure appears in the form of peeling, flaking, or a cloudy appearance that negatively affects your property's business image. Failed sealers also undermine protection, allowing water and chemicals to penetrate and harm the underlying concrete.

Surface preparation for new coatings typically involves the complete removal of sealer. New sealers might not adhere well over existing coatings, which can result in early failure and additional maintenance expenses. It is preferable to begin with a clean concrete surface when installing new protective systems.

Color changes or aesthetic updates often propel sealer removal projects. Your business may require a unique look that cannot be achieved with pre-installed sealers. If this is the case, a total removal allows you to achieve your desired result.

Contamination problems occasionally warrant sealer removal and replacement. Oil spills, chemical exposure, or other contaminants can irreparably discolor sealers. Instead of settling for an imperfect appearance, sealer removal allows you to correct the defects.

Maintenance access is another legitimate reason to remove sealers. Certain repair methods need unsealed concrete for the adhesion of repair materials.

Additionally, you must consider the age and condition of existing sealers when planning maintenance schedules. Most commercial sealers require replacement every three to five years, depending on traffic levels and environmental exposure. Proactive removal and replacement prevent sudden sealer failure that could disrupt business operations.

California's environmental conditions, such as UV exposure and temperature cycling, hasten sealer degradation. Periodic inspection detects initial signs of failure before the total breakdown of the sealer. Quick intervention is required after detection to reduce expenses.

Budget also impacts timing choices. Scheduling sealer removal during periods of low business activity reduces operational interference while providing sufficient time for surface preparation and resealing.

Effective stripping of concrete sealers starts with identifying the sealer type and selecting the appropriate removal method.

Concrete sealer removal is a process that needs to be carefully planned, with the right equipment and an understanding of safety regulations in California. A strategic, well-executed approach allows you to restore concrete surfaces while preparing them for advanced protection systems.

For more information about concrete materials and maintenance, check out our related articles, “Concrete Slab

Foundation Repair” and “How to Fix

Cement Steps”. For more information on how to deal with other issues with concrete, you can also visit

our blog.

At

TMC

Engineering, we’re not just about getting the job done—we’re about doing things right. With every project, our focus is on

safety, quality workmanship, and client satisfaction. Whether it’s

asphalt

paving,

striping,

sealing, or

concrete work, our

team of experts is here to help you understand the process. If you’re tackling a project like stripping concrete sealer, you’re in the right place.

Contact us today

to discuss your needs and receive a customized proposal. We’re committed to building lasting partnerships by delivering quality-driven solutions.