Stamped Concrete Paint: Updating Decorative Concrete Surfaces with Paint

Concrete provides a durable, versatile building material with many applications beyond basic foundations and slabs. Decorative concrete techniques allow for customized aesthetics through stamping, coloring, and other texturing methods . We discussed some of these in our post on concrete parking lot repair .

Stamped concrete in particular can create realistic faux stone, brick, slate, tile, or wood finishes for driveways, walkways, and patios. Over time, those stamped concrete surfaces may show normal wear that compromises the illusion of the artificial appearance. Painting can help refresh the concrete and restore the stamped illusion.

Today we will explore how stamped concrete paint brings new life and curb appeal.

Stamped Concrete Paint

Stamped concrete paint is a specialized acrylic-based coating formulated to adhere properly to pre-existing stamped and colored concrete. Unlike standard exterior house paints, stamped concrete paints are breathable, allowing moisture from below to still dissipate instead of getting trapped. This maintains the concrete’s integrity and intended purpose.

Concrete paint also flex es with concrete’s natural movement to prevent flaking or peeling over many weather cycles. Available in a wide array of natural stone, brick, and terrazzo patterns, painting stamped concrete is a cost-effective way to revitalize aged surfaces without intensive demolition and replacement.

How To Paint Stamped Concrete

Step 1 – Clean and p rep the s urface .

Thoroughly power-wash stamped concrete to remove surface dirt, debris, oil deposits, or existing sealers. Allow it to fully dry before proceeding. Address any deeply worn or damaged areas with a concrete patch prior to painting. Grind or sand rough sections for optimal adhesion. Remove all concrete grindings and dust with compressed air.

Step 2 – Fill c racks and s eal the s urface.

For added protection against water intrusion, apply high-quality concrete crack filler to any hairline fractures present. Also, ensure the concrete has been sealed beforehand. Quality sealers fill pores to prevent stamped concrete paint from soaking in unevenly.

Step 3 – Prime the s urface .

The roller applies a high-quality concrete primer, ensuring complete coverage , including edges. The primer bonds the paint to the substrate and provides a uniform base coat color. Allow the primer to fully dry as per instructions, usually 4-8 hours depending on the weather. Here is more information on optimal weather conditions for concrete work .

Step 4 – Apply p aint in t hin c oats .

Using a small roller, brush, or high-quality sprayer, apply the first thin coat of stamped concrete paint. Work in small sections for coverage before the paint starts to dry. Multiple thin coats generally provide better results than one thick coat.

Step 5 – Add d etail with s tamped c oncrete p aint .

For extra realism once the base color coat is dry, lightly ‘stamp’ on decorative concrete accents like grout lines using a small sponge or brush. Multiple light coats recreate natural faux details and provide sealing between color coats.

Step 6 – Add a dditional c oats and s ealing .

Once the first coat dries, apply a second and then a third thin coat as directed by the paint manufacturer. Three coats usually give full coverage and restoration of the faux finish. Finally, protect with a high-quality water-based concrete sealer for durability against foot traffic and weathering.

Benefits of Painting Stamped Concrete

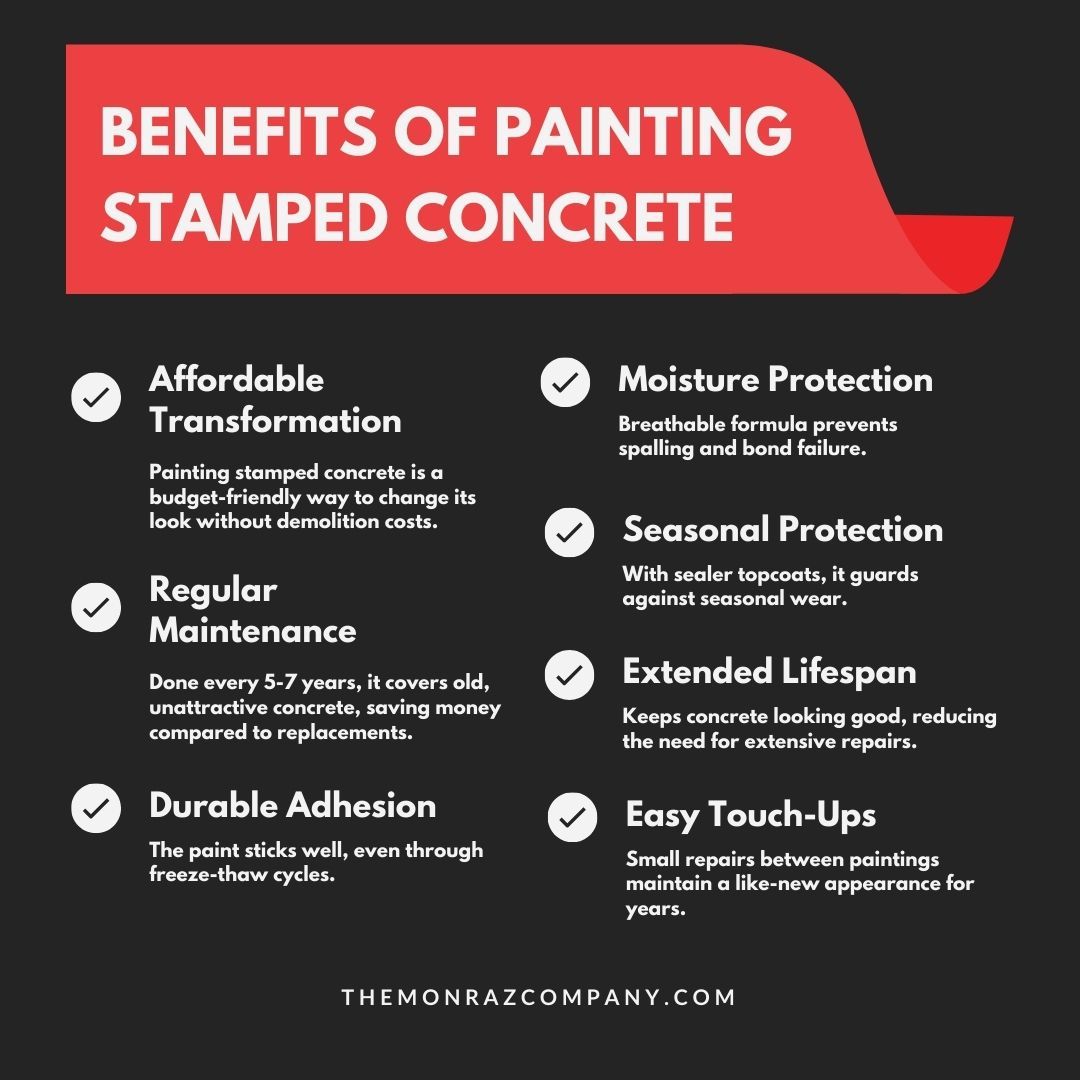

Painting provides an easy, affordable way to completely transform existing stamped concrete’s appearance without demolition. It can prolong necessary concrete replacement as well if done every 5-7 years and before wear gets extensive. Old unappealing gray or stained concrete with plenty of life left in it hides discretely beneath fresh new faux finishes.

Paint adheres securely to well-sealed concrete, resisting flaking even through freeze-thaw cycles. Breathable formula s allow moisture vapor transmission, preventing spalling and bond failure. With proper sealer topcoats added, concrete surfaces stay protected season after season.

The painting extends stamped concrete’s useful lifespan by refreshing its finish before the damage gets too worn for simple patching. Small repairs or touch-ups between full paintings maintain like-new appearances for many more years of safe use and enjoyment.

Apply your stamped concrete paint the right way with the right professionals for the best results

By following these painting best practices, homeowners refresh the look of stamped concrete for years to come without the hassle or expense of full removal and replacement. For larger commercial jobs, contact professional decorative concrete contractors. Their specialized experience and tools ensure long-lasting, properly coated stamped concrete surfaces as discussed in our post When to Pour Concrete .

Whatever your asphalt pavement needs are, relying on professionals like TMC Engineering ensures fast, compliant work addressed by certified crews with proper removal know-how. Hiring an asphalt and concrete contractor like us saves you from the dangers and difficulty of do-it-yourself removal with heavy machinery!

Our team has the proper training, equipment, and expertise to efficiently complete this physically demanding phase. Contact us today for your FREE QUOTE!