Dry Pouring Concrete Slab: A Complete Guide for Commercial Properties

Concrete slabs anchor every major commercial construction project, yet most property managers stick with conventional wet-pour methods without exploring alternatives. Here's the reality: traditional concrete placement often creates headaches with weather delays, equipment access issues, and rushed timelines that compromise quality.

Well-informed contractors have discovered that different concrete placement techniques solve different problems. Wet pouring works great when you have perfect conditions and unlimited truck access. But what happens when you're renovating a basement retail space or building in a tight urban location where concrete trucks can't maneuver?

This guide outlines the dry pouring concrete slab method, examining how it works and where it excels. We will examine this method’s structural performance, durability, and suitability for commercial applications.

If you’d like a quicker or more specific answer to your asphalt or concrete repair questions, call the experts at

TMC Engineering! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution for your commercial concrete or asphalt concerns!

Dry Pouring Concrete Slab: What You Need to Know

This comprehensive breakdown equips you with everything you need to assess dry-pour concrete for your next commercial project. You'll gain insight to its advantages, potential limitations, and scenarios where this method outperforms traditional approaches.

Furthermore, we'll address common concerns about dry pouring reliability and provide step-by-step implementation guidance. Whether you're managing a small commercial renovation or overseeing large-scale construction, this information helps you evaluate dry pouring as a viable option for your concrete needs.

Most importantly, you'll learn to recognize when dry pouring makes sense versus when you should stick with conventional methods. Property managers who understand these distinctions save money, reduce project delays, and achieve better outcomes for their commercial spaces.

What Is A Dry Pour Concrete Slab?

Picture this: instead of mixing water with cement and aggregate before pouring, you spread dry concrete ingredients directly onto your prepared surface. Then, you carefully add water from above. This allows gravity and time to create the chemical reactions that turn loose materials into solid concrete.

This fundamental shift changes everything about timing and logistics. Traditional mixing concrete requires precise coordination you've got maybe 90 minutes from batching to placement before the mixture becomes unusable. Dry pouring, on the other hand, eliminates that countdown pressure entirely.

The process works through controlled hydration rather than mechanical mixing. Water penetrates downward through the dry materials while cement particles activate gradually. This creates a different curing environment compared to pre-mixed concrete, with some surprising benefits for specific applications.

Commercial projects often struggle with access limitations that make traditional concrete trucks impractical. Narrow doorways, weight restrictions on upper floors, or sites without adequate turning radius can make wet pouring nearly impossible. To solve these access challenges, dry pouring uses materials that workers can carry in bags.

However, success depends entirely on understanding how water moves through a dry concrete mix. Unlike wet concrete where everything's already blended, dry pouring requires patience and technique to achieve uniform hydration throughout the slab.

How Does A Dry Pour Concrete Slab Work?

The mechanics behind dry pouring reveal why this method succeeds in situations where traditional concrete fails. Understanding these principles helps you decide whether it fits your specific project requirements. Let’s take a look at exactly how this process works so you can feel fully prepared for your next job.

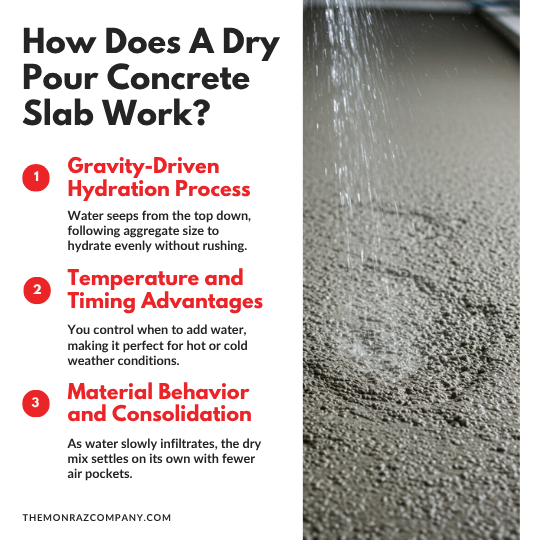

Gravity-Driven Hydration Process

Water starts at the surface and works downward through the dry mix layers. This isn't random; it follows predictable patterns based on particle size distribution and mix composition. Larger aggregate creates channels that guide water flow, while finer particles distribute moisture sideways through smaller spaces in the mix.

This downward progression actually mimics how concrete naturally wants to cure. Instead of fighting against time limits imposed by pre-mixing, you're working with the material's inherent properties. The result often produces more uniform hydration than rushed wet pours.

Temperature and Timing Advantages

Dry pouring gives you control over hydration timing that wet concrete simply can't match. Hot weather that ruins traditional pours becomes manageable when you control when and how fast water contacts cement particles. Those of you working in the hot and humid California weather know how crucial this can be. On the contrary, cold conditions that slow wet concrete curing can actually benefit dry pour strength development.

This flexibility proves invaluable for commercial projects with tight scheduling constraints. You can place dry materials during optimal weather windows, and then add water when conditions favor proper curing. No more canceled pours due to unexpected temperature swings.

Material Behavior and Consolidation

Dry mix settles and consolidates differently than wet concrete. Instead of requiring mechanical vibration to eliminate air pockets, dry pouring relies on gradual settling as water infiltration progresses. This natural consolidation often produces fewer gaps than rushed wet pours.

However, achieving proper consolidation requires understanding how different aggregate sizes affect water penetration. Mixes designed for wet pouring may not perform optimally with dry placement techniques. Success demands matching mix design to placement method.

Is A Dry Pour Concrete Slab Strong?

Industry experts remain divided on dry pour concrete strength, but recent testing reveals some surprising results. The short answer: properly executed dry pours can match or exceed wet concrete strength. But, note that achieving those results requires different skills than traditional concrete work.

Structural engineers who've studied dry-pour concrete report compressive strengths ranging from 85% to 110% of equivalent wet-mixed concrete. The wide range doesn't reflect the method itself, but more so how carefully the method was applied. Essentially, you will often find that skilled contractors consistently achieve the higher end of this spectrum.

The controversy over dry pouring stems from quality control challenges. Wet concrete allows testing and adjustment before placement, whereas dry pouring requires trusting the process and monitoring hydration progress indirectly. This uncertainty makes some engineers nervous about structural applications.

However, contractors specializing in dry pouring techniques report excellent long-term performance. They've learned to read visual cues that indicate proper hydration and developed testing methods specific to dry pour applications. Their success rates often exceed those of general contractors who just attempt the technique occasionally.

The takeaway is that dry pour concrete isn't automatically weaker than wet concrete, but

it requires different expertise to execute properly. Property managers considering this method should work with contractors who specialize in dry pouring rather than those treating it as an occasional alternative.

How To Dry Pour A Concrete Slab

Success with dry pouring demands thorough application and attention to details that are less critical with wet concrete. These steps reflect lessons learned from commercial projects where the method delivered excellent results.

Step 1: Prepare the foundation.

First, excavate to the proper depth and pay extra attention to drainage since dry pouring creates different water management challenges. Next, install a compacted stone base slightly thicker than what wet concrete requires; the extra material aids water distribution during hydration. Finally, place vapor barriers carefully, ensuring there are no tears that could create uneven moisture conditions. Poor base preparation causes more problems with dry pouring than wet concrete because you can't correct issues after placement begins.

Step 2: Engineer formwork for dry materials.

Because dry materials create different pressure patterns, build forms stronger than those used in typical wet concrete applications. The dry mix settles and shifts during water application, potentially pushing against forms in unexpected ways. To help with stability and failure prevention, install reinforcement and pay extra attention to positioning. Remember, you won’t have a concrete flow to help the material settle around steel. And, don’t forget to check elevations multiple times dry pouring offers less tolerance for grade corrections than wet concrete.

Step 3: Distribute the dry mix strategically.

Spread dry materials using techniques that prevent segregation of cement and aggregate. Since redistributing dry mix often separates particles by size, avoid dumping large quantities in single locations. Once you pour the materials, use rakes and screeds designed for dry materials. If you use wet concrete tools, you run the risk of uneven distribution, poor compaction, and a weaker finished slab. As you work to create consistent thickness across the entire area, pay special attention to corners where material tends to accumulate unevenly. The goal is uniform distribution that supports even water penetration.

Step 4: Introduce the controlled water.

As you introduce controlled water, begin with a light mist rather than a heavy soak. Spray equipment works well for this, delivering fine droplets instead of a solid stream that may wash away cement particles. Start water application at one end and work systematically across the surface for even moisture distribution and consistent hydration. And, watch for color changes that indicate proper wetting without oversaturation. This step requires patience, rushing water application creates weak spots that compromise the entire slab.

Step 5: Manage progressive hydration.

Continue water application in multiple passes, allowing each application to penetrate before adding more. Make sure to monitor surface firmness to gauge hydration progress. You’re looking for the concrete to gradually transition from loose powder to a more solid, cohesive material. When necessary, adjust water application rates based on ambient temperature and humidity. In hot, dry conditions like those often seen in California you will need frequent light misting. In contrast, cool, humid weather needs less frequent but more thorough watering.

Step 6: Finish the surface.

Once the concrete reaches the proper consistency, begin finishing operations using appropriatetools for concrete selected for dry pour applications. The extended working time allows more detailed finishing than rushed wet pours. Float and trowel the surface to achieve the desired texture while maintaining consistent moisture levels. Finish by applying any required surface treatments before the concrete becomes too firm to accept them properly.

Step 7: Extended curing and quality monitoring.

Implement curing procedures that account for the gradual hydration characteristic of dry-pour concrete. For example, keep surfaces moist longer than you would for typical wet concrete since hydration continues for extended periods. Use curing compounds designed for slower-hydrating concrete or maintain moist conditions through covering systems. At the same time, monitor strength development through appropriate testing methods. It’s important to understand that dry pour concrete may reach design strength slower more slowly but often achieves higher ultimate strength.

The success of dry pouring depends on recognizing that this method requires different skills than traditional mixing concrete approaches. When executed by knowledgeable contractors like

TMC Engineering, dry pour concrete offers solutions for commercial projects where conventional methods create logistical or quality challenges.

Dry pouring is an efficient and cost-effective alternative for commercial properties.

Property managers should carefully evaluate whether their specific project requirements align with dry pouring capabilities. The method excels in certain situations while creating unnecessary complications in others. Understanding these distinctions helps you make informed decisions that benefit your commercial property investments.

Consult our

blog for more information on all things around concrete. We have other informative posts such as

concrete slab foundation repair and

concrete

parking

lot repair.

Our team of experienced paving professionals at TMC Engineering provides a wide range of transportation construction services to meet all of your project needs. Whether you need

asphalt paving, parking lot

striping, sealing, or

concrete work completed, we have the expertise and equipment to handle the job efficiently and cost-effectively. By combining extensive industry knowledge with high-quality materials and workmanship, we can deliver durable, long-lasting results!

Contact us today to discuss your requirements and receive a customized proposal. We aim to forge strong partnerships through collaboration on quality-focused solutions!