Masonry Wall Anchors: All You Need To Know

When it comes to working on masonry surfaces, whether it's a brick wall, concrete block, or natural stone, having the right tools and fasteners is crucial for ensuring the long-term durability and stability of your project. Masonry wall anchors play a vital role in this regard, providing a secure and reliable means of attaching various fixtures, shelves, or even heavy-duty equipment to these rugged,more challenging surfaces.

In this guide, you’ll learn what masonry anchors are, how they work, and how to install them effectively for maximum holding power. By understanding the ins and outs of masonry anchors, you'll be better equipped to tackle your next masonry project with confidence and ensure that your work stands the test of time.

If you would like a quicker or more elaborate answer to your repair and construction questions, call the experts at TMC Engineering! If you're in Southern California, we can instruct you on your problem and perform whatever repair is necessary. We've got an expert solution for all your asphalt or concrete needs!

What Are Masonry Wall Anchors?

Masonry wall anchors are specialized fasteners designed to securely attach objects such as shelves, cabinets, or heavy equipment to masonry surfaces like concrete, brick, or concrete block walls. These anchors are typically made from corrosion-resistant materials, such as stainless steel or hot-dip galvanized steel, to withstand the harsh conditions often encountered in masonry environments.

Masonry wall anchors are highly effective in providing a stable and long-lasting connection, as they are engineered to expand or grip within the drilled hole, creating a tight, secure hold within the masonry material. This level of holding power is crucial, as masonry surfaces can be more challenging to work with compared to drywall or wood, and require a more specialized approach to ensure a safe and reliable installation.

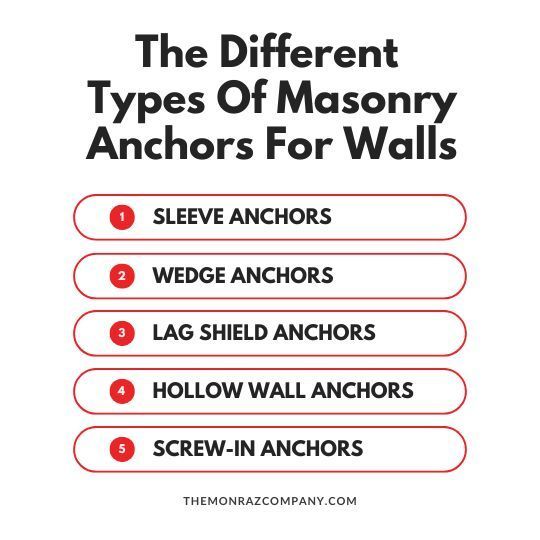

What Are The Different Types Of Masonry Anchors For Walls?

Sleeve Anchors

Sleeve anchors, also known as expansion anchors, are one of the most common types of masonry wall anchors. These anchors feature a threaded metal, surrounded by a metal sleeve or shell. When the bolt is tightened, the sleeve expands within the drilled hole, creating a tight, secure grip on the masonry material. It has a holding power of 200 to 1,000 lbs, depending on diameter. Sleeve anchors are versatile and can be used in both solid and hollow masonry walls.

Wedge Anchors

Wedge anchors are similar to sleeve anchors, but they use a tapered, split-wedge design rather than a sleeve. When the bolt is tightened, the wedge expands, creating a strong hold within the drilled hole. Wedge anchors are often used in solid masonry materials, such as concrete or brick, and are known for their exceptional holding power of up to 3,000 lbs in shear strength.

Lag Shield Anchors

Lag shield anchors are a type of masonry anchor designed to work with standard lag screws. The anchor is first inserted into a pre-drilled hole, and then the lag screw is driven into the shield, causing it to expand and grip the masonry material. Lag shields are commonly used for attaching heavy-duty fixtures or equipment to masonry walls.

Hollow Wall Anchors

Hollow wall anchors, also known as molly bolts or wall anchors, are specifically designed for installation in hollow masonry materials, such as concrete block or masonry veneer. These anchors feature a threaded metal shell that expands within the drilled hole, creating a secure grip on the interior surface of the hollow wall.

Screw-In Anchors

Screw-in anchors, as the name suggests, are masonry anchors installed by simply screwing them directly into a pre-drilled hole in the masonry material. These anchors are often used for lighter-duty applications and are relatively easy to install, making them a popular choice for DIY projects.

How Do Masonry Anchors Work On Walls?

Masonry wall anchors work by creating a secure, mechanical connection within the masonry material, such as concrete, brick, or concrete block. The basic principle is that the anchor is inserted into a pre-drilled hole and then expands or grips the interior of the hole, forming a tight, interlocking bond with the surrounding masonry.

The specific mechanism by which each type of masonry anchor works can vary, but they generally fall into one of two categories:

- Expansion Anchors: These anchors, such as sleeve anchors and wedge anchors, feature a component (like a sleeve or wedge) that expands when the anchor is tightened. This expansion creates a secure grip within the drilled hole.

- Friction-Fit Anchors: Anchors like screw-in anchors and lag shield anchors rely on the friction between the anchor and the walls of the drilled hole to create a strong hold. The unique design and materials of these anchors allow them to grip the masonry material tightly.

The key to the effectiveness of masonry wall anchors is the ability to create a tight, secure connection that can withstand the weight and forces exerted on the attached object. This is why proper installation techniques, the use of appropriate drill bits, and the selection of the right anchor type for the masonry material are all critical factors in ensuring the long-term stability and safety of your masonry project.

How To Install Masonry Anchors On Walls

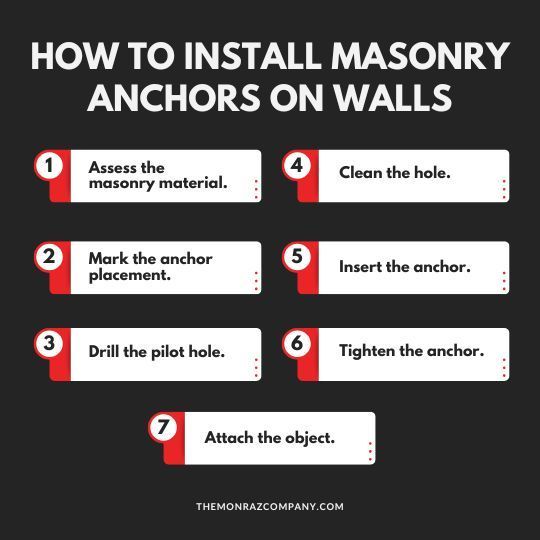

Step 1: Assess the masonry material.

Carefully examine the wall surface to determine the type of masonry material you are working with, whether it's concrete, brick, or concrete block. This will help you select the appropriate anchor type and size for the application.

Step 2: Mark the anchor placement.

Carefully measure and mark the desired locations for the anchor(s) on the masonry wall. Make sure to account for any obstructions or utilities behind the wall that could interfere with the anchor placement.

Step 3: Drill the pilot hole.

Step 4: Clean the hole

Remove any debris or dust from the drilled hole using a vacuum attachment or compressed air. This ensures a clean surface for the anchor to grip properly.

Step 5: Insert the anchor.

Carefully insert the masonry anchor into the drilled hole, following the manufacturer's instructions. For expansion anchors, this may involve tapping the anchor in with a hammer to ensure it is properly seated. For lag shield anchors, tap the shield flush with the surface.

Step 6: Tighten the anchor.

Use a wrench or socket to tighten the anchor according to the manufacturer's recommended torque specifications. This step is crucial for ensuring the anchor creates a secure, reliable hold within the masonry material.

Step 7: Attach the object.

Once the anchor is properly installed, you can attach the desired object, such as a shelf, cabinet, or equipment, to the masonry wall using the appropriate hardware (e.g., screws, bolts).

Masonry wall anchors bridge the gap between sturdy masonry and secure installations.

Remember, the success of your masonry anchor installation relies on several factors, including the condition of the masonry material, the selection of the right anchor type, and the proper installation technique. Refer to the manufacturer's instructions and consider consulting with a professional if you are unsure about any aspect of the process.

At TMC Engineering, we have a deep commitment to delivering projects characterized by the highest standards for safety, workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides!

Whether you require asphalt paving, striping, sealing, or concrete work, we offer a full suite of transportation construction solutions. Look no further we’ve got all you need and more!