Different Types of Asphalt

Asphalt is one of the most widely used pavement materials around the world! However, different types of asphalt can be used for various applications. The optimal asphalt choice depends on factors like the project’s needs, environmental conditions, and costs.

While asphalt pavement provides an effective surface for driving and parking vehicles, not all asphalt varieties are the same. Certain properties make some asphalt types better suited for highways, others for residential streets, and some may have advantages for temporary patching. The production method, materials used, and installation processes will vary between asphalt kinds as well.

Today, we will explore the various types of asphalt that are commonly used in pavement construction and maintenance. By understanding the characteristics of each, one can select the right asphalt for a job’s particular requirements. Certain situations may even call for combining specific asphalt mixes!

Let’s begin our overview of the different kinds of asphalt available!

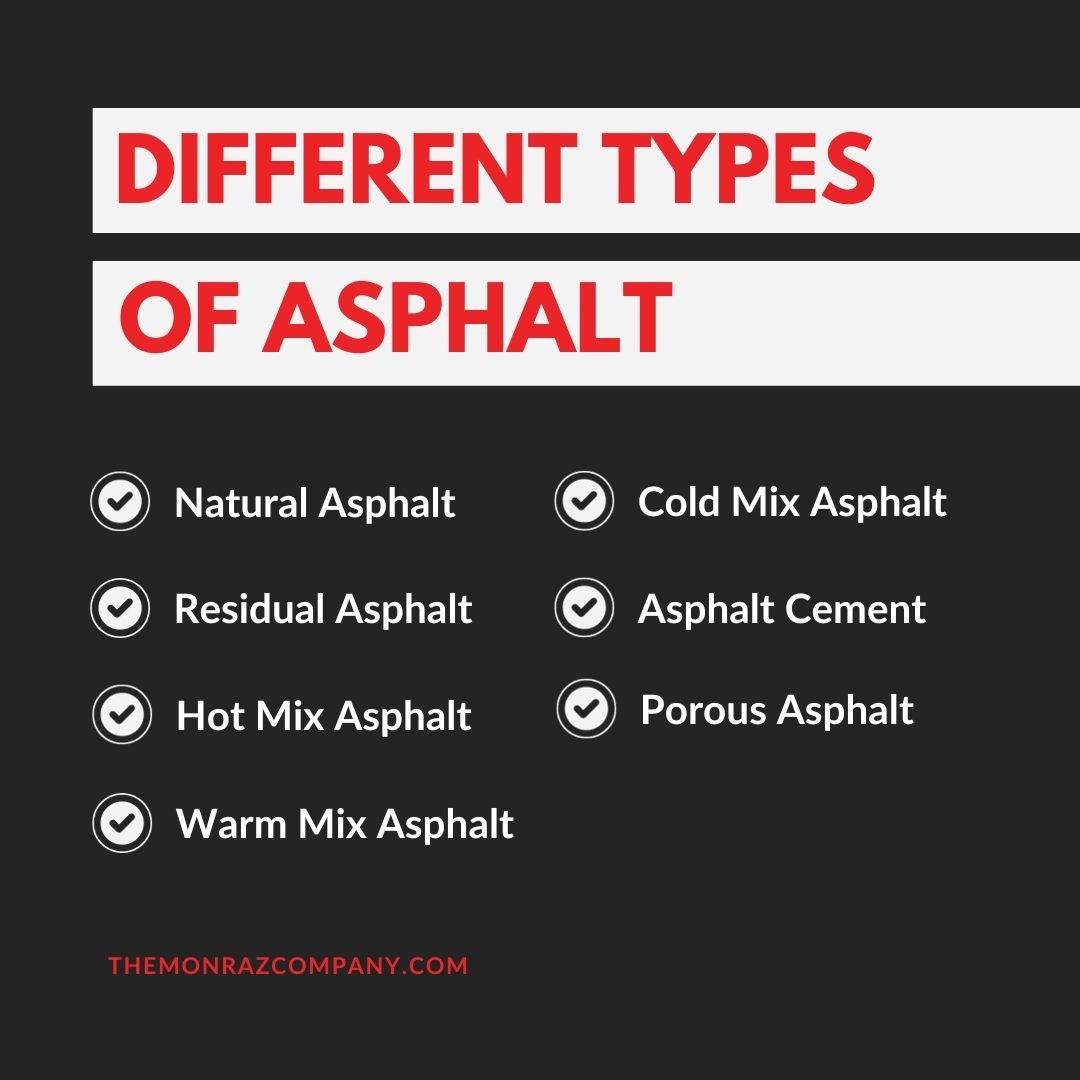

Different Types of Asphalt

There are several types of asphalt mixes used for various pavement applications. Below are some of the common ones:

Natural Asphalt

Formed through natural processes deep underground over thousands of years, natural asphalt is a type of bitumen with ancient origins. The remains of prehistoric plants and animals deposited in marine environments slowly broke down under heat and pressure, transforming into dense, complex hydrocarbon molecules. This process of fossilization created natural deposits of asphalt through gradual geological changes.

Due to its slow underground development, natural asphalt possesses distinct properties that make it suited for preservation applications even today. Its heavy, non-volatile composition provides natural asphalt with exceptional durability for sealing, waterproofing, and other uses. Plus , the adhesive nature intrinsic to natural asphalt from its formation lends it enduring weather resistance.

Residual Asphalt

Residual asphalt is a byproduct of the oil refining process. After distilling crude oil, the leftover heavy residue contains asphalt binder components. This binder shows viscosity suitable for use in asphalt paving mixtures.

The refining process alters and concentrates the asphalt compounds in residual bitumen compared to natural bitumen. It has properties like adhesion, water resistance, and durability at high and low temperatures needed for pavement applications. Residual asphalt is one of the primary ingredients used in many modern asphalt concrete mixes.

Hot Mix Asphalt

Hot mix asphalt (HMA) consists of aggregate materials coated with residual asphalt binder and laid at high temperatures. This allows the binder to surround fine and coarse aggregates when compacted. Proper coating creates a dense, waterproof paving material with strength to support heavy vehicle loads.

HMA sets as it cools and hardens into a durable, flexible pavement. Contractors precisely control the mix design, installation process, and compaction of HMA to meet quality standards. Its structural integrity makes it suitable for major roads, highways, and parking lots requiring multiple layered systems and long service life.

Fine-graded HMA provides structural integrity beneath multiple pavement layers for high-traffic roads, highways, and parking lots. Likewise with dense-graded mixes too!

Warm Mix Asphalt

Warm mix asphalt (WMA) can be produced and laid at significantly lower temperatures than HMA, ranging from 230-300°F . This is made possible through chemical or foaming processes that allow compacting and coating of aggregates at warmer temperatures.

The use of WMA provides cost savings since less fuel is required for plant operations and hauling. It also reduces environmental impacts through lower emissions during production and placement compared to hot mix. Overall , WMA maintains sufficient workability and strength for low to moderate-traffic applications.

Cold Mix Asphalt

Cold mix asphalt, often called cold patch, uses an asphalt emulsion or cutback asphalt instead of heated liquid asphalt cement. This enables the coating and laying of aggregates at temperatures as low as 40°F without the need for any heating process.

Cold mix asphalt is a simple temporary fix for cracks and potholes that hardens without heat. It uses coarse-graded aggregates unsuitable for structural layers. MC cold mix from certain suppliers hardens quickly for patching in cold temperatures.

While cold mix offers a simple, cost-effective solution for temporary patching of potholes or trenches, it has limited structural integrity. The mix design uses coarse aggregates unsuitable for weight-bearing pavement layers. It is not able to achieve the density and performance of heated mixes.

Asphalt Cement

Asphalt cement is a sticky, highly viscous liquid that is produced from residual crude oil bitumen. It forms the bonding agent used to adhere aggregates together in asphalt concrete mixtures. Proper viscosity and adhesion properties are needed to ensure good coating, densification, and long-term flexibility.

Contractors may also use asphalt cement for sealcoating and preventative maintenance of existing pavement surfaces. This helps prolong the life of the asphalt and protect it from damage from weather and traffic.

Porous Asphalt

Porous asphalt pavement contains a percentage of air voids between the aggregate materials that are connected, allowing water to drain through the surface. During production and installation, we deliberately incorporate these interconnected voids.

Compared to impervious asphalt, porous asphalt uses aggregate blends with larger particle sizes and more air space between pieces. This offers permeability to reduce stormwater runoff from paved areas by allowing filtration and drainage.

Properly installed porous asphalt can help minimize localized flooding issues during heavy rains. It is a suitable permeable pavement choice for low-traffic applications like emergency access roads and driveways. Ongoing maintenance is required to keep the surface from clogging and preserving its intended hydraulic function.

Choosing the proper asphalt mix is vital to ensure long-term performance and value.

As we’ve seen, factors like traffic conditions, climate exposures, and desired porosity all influence asphalt material selection. Contractors must also consider construction details such as timelines, temperatures, and handling properties. Implementing optimal paving solutions that suit diverse pavement applications becomes possible with an informed perspective of the various asphalt options.

Whether it’s a high-volume highway, residential street, parking lot, or bike trail, asphalt remains one of the most ubiquitous and flexible paving materials. Continued innovation within the industry helps deliver even more sustainable and cost-effective asphalt products. A thorough evaluation of project specifics aids in specifying the asphalt type or blend that best meets durability, environmental, and budgetary objectives.

Our team of experienced paving professionals at TMC Engineering provides a wide range of transportation construction services to meet all of your project needs. Whether you need asphalt paving , striping, sealing , or concrete work completed, we have the expertise and equipment to handle the job efficiently and cost-effectively. By combining extensive industry knowledge with high-quality materials and workmanship, we can deliver durable, long-lasting results!

Contact us today to discuss your requirements and receive a customized proposal. We aim to forge strong partnerships through collaboration on quality-focused solutions!