How Is Asphalt Made?

Though many may not give it much thought, asphalt is one of the unsung heroes that paved the way for our modern infrastructure. From roads and bridges to tunnels and pavements, asphalt is everywhere. It silently endures the weight of heavy traffic and provides us with durable and reliable surfaces!

Despite its ubiquitous presence, many people have little knowledge of how this remarkable material is actually made. That’s why we’ve dedicated this post to explaining the asphalt manufacturing process. We will be looking at the behind-the-scenes work that goes into producing this essential building block of our modern world!

Read on as we look into the processes that transform basic raw materials into the resilient asphalt we see all around us!

Let’s get started!

How Is Asphalt Made?

Asphalt is typically made using a process called the “ hot mix asphalt ” method. This is the most common method used for large-scale projects such as highways and major roadways. However, there are also other methods like “ warm mix ” and “ cold mix asphalt ” that offer their own unique advantages in specific situations.

When it comes to the process of asphalt manufacturing, its durability and performance depend on a combination of factors. It all begins with the careful selection of materials and the precise processing that asphalt undergoes. Materials include the aggregates, which are chosen for their strength and stability, and the asphalt cement, which acts as the binder that holds everything together. The meticulous blending of these ingredients ensures that each aggregate particle is uniformly coated with the asphalt cement. This creates a cohesive mixture that can withstand the test of time. Durability at its best!

What makes asphalt truly remarkable is its ability to last for decades when properly designed and maintained. The careful selection of materials, the precise processing, and the meticulous blending and compaction all contribute to its longevity. With periodic maintenance and adherence to quality standards, asphalt surfaces can continue to perform at a high level. That right there, is the beauty of asphalt!

Where Does Asphalt Come From?

The primary ingredients used in making asphalt are aggregates and asphalt cement, also known as bitumen . Aggregates include materials like sand, gravel, and crushed stone, which provide the strength and stability needed in the final product. Furthermore, these aggregates are carefully selected and processed to meet specific requirements for different types of projects.

Asphalt cement is the binder that holds the aggregates together and gives asphalt its characteristic properties. Asphalt cement is derived from crude oil during the refining process. Different grades of asphalt cement are available, each with its own characteristics and performance attributes. The choice of asphalt cement grade depends on factors such as the intended application, climate conditions, and desired durability.

Asphalt cement is carefully blended with the aggregates in a mixing plant, creating the hot mix asphalt that is used for various construction projects. The proportions of aggregates and asphalt cement can be adjusted to meet specific project requirements, ensuring the desired performance and durability of the asphalt pavement.

It’s worth noting that the quality and performance of asphalt can vary depending on the materials used and the manufacturing processes employed. This is why it’s important to work with reputable suppliers and contractors who understand the nuances of asphalt production. Yes, you thought right – we’re the right experts to consult !

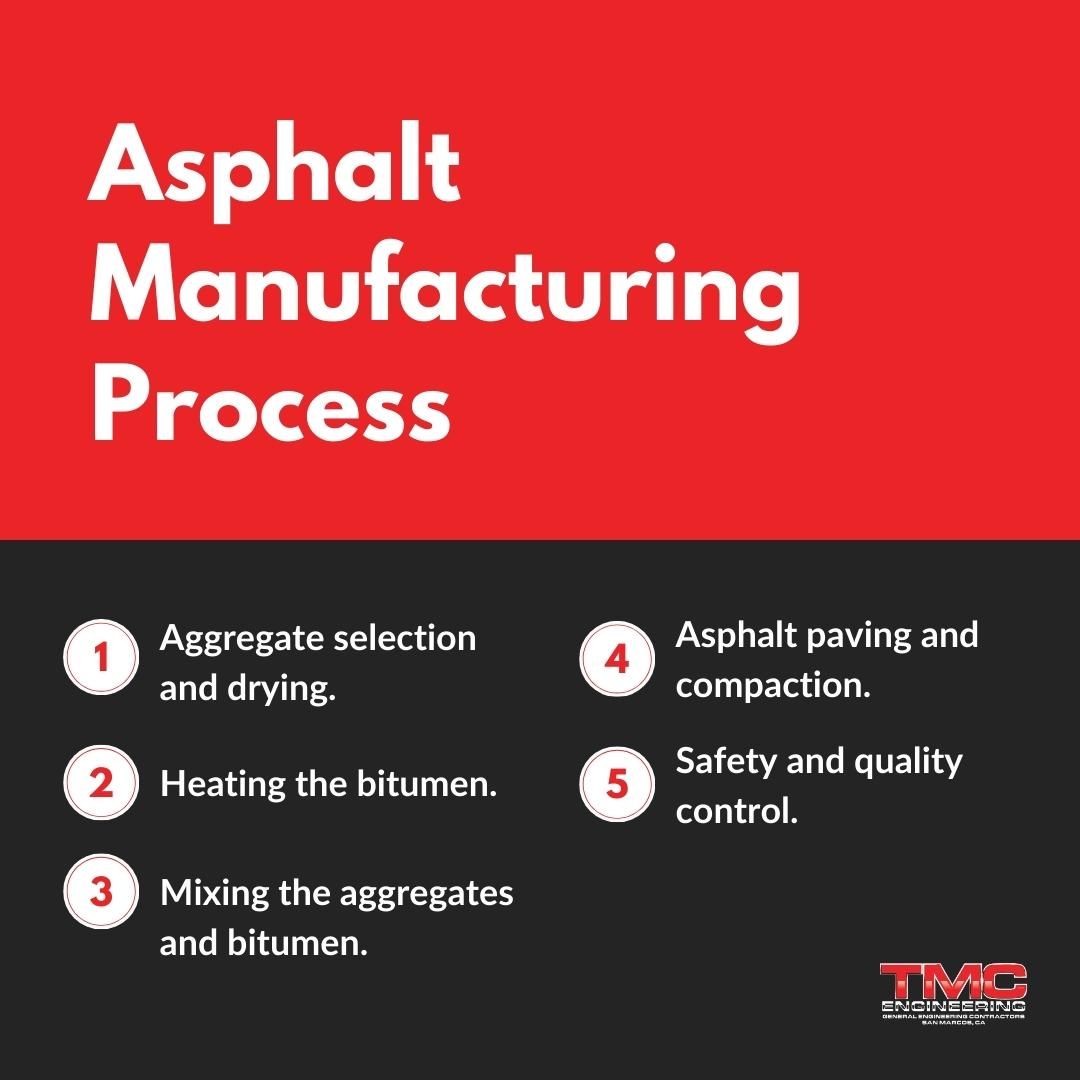

Asphalt Manufacturing Process

The asphalt manufacturing process begins with the careful selection and combination of aggregates, such as sand, gravel, and crushed stone, along with a binder called bitumen. Bitumen is a sticky, black, and highly viscous material derived from petroleum.

Step 1: Aggregate selection and drying.

The first step in producing hot mix asphalt is selecting the appropriate aggregates. These aggregates are then carefully dried to remove any moisture, ensuring proper adhesion with the bitumen binder. Drying the aggregates helps to create a strong and durable asphalt pavement!

Step 2: Heating the bitumen.

While the aggregates are being dried, the bitumen is heated separately to a high temperature. This heating process makes the bitumen more fluid and easier to mix with the aggregates. It also helps to ensure proper coating and adhesion of the aggregates, resulting in a cohesive asphalt mixture.

Step 3: Mixing the aggregates and bitumen.

Once the aggregates and bitumen are prepared, they are combined in a mixing plant. The mixing plant carefully blends the heated bitumen with the dried aggregates to create a homogeneous mixture. This mixture is then transferred to trucks for transportation to the job site.

Step 4: Asphalt paving and compaction.

Upon arrival at the job site, the hot mix asphalt is unloaded and immediately laid on the prepared surface for paving. This is where expertise comes in! Skilled workers use pavers and rollers to spread and compact the asphalt mixture. This compaction process ensures that the asphalt pavement is dense, smooth, and durable.

Step 5: Safety and quality control.

Throughout the entire asphalt manufacturing and paving process, strict safety standards must be followed to ensure the well-being of workers and the public. Quality control measures, such as testing the mixture’s temperature, density, and composition, are also implemented to guarantee the longevity and performance of the asphalt pavement.

When it comes to warm mix and cold mix asphalt, the manufacturing process differs slightly. Warm mix asphalt uses additives to lower the temperature at which the bitumen is mixed with the aggregates, reducing energy consumption and emissions. Cold mix asphalt, on the other hand, is produced without heating the aggregates or bitumen, making it suitable for quick and temporary repairs.

Understanding how asphalt is made helps us appreciate it more.

Asphalt plays a vital role in our everyday lives, providing us with safe and reliable surfaces for transportation and recreation. Whether it’s constructing roads, parking lots, and driveways, or carrying out asphalt repair, understanding the asphalt manufacturing process is important. It helps us appreciate the hard work and attention to detail that goes into creating these essential structures!

So, the next time you drive on a smooth and well-paved road, remember to take a moment to appreciate the intricate process involved in producing the asphalt beneath your wheels. It’s a testament to the dedication of those who work in the asphalt industry and their commitment to maintaining high-quality standards!

At TMC Engineering, we’re committed to quality and safety alongside other needed metrics for excellence. Stay tuned for even more informative posts and exciting updates from our page . In need of a wide range of services from asphalt paving to striping, sealing, crack filling , and concrete projects ? Look no further! TMC Engineering has got you covered. Contact us today for a free quote ! Together, we can complete exceptional projects that stand the test of time!