How To Fix Potholes In Gravel Driveway

Here at TMC Engineering , we have a deep commitment to delivering projects characterized by the highest standards for safety , workmanship, and client satisfaction. Whether it’s gravel driveways with edging or parking lot striping , we aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further–we’ve got all you need and more!

Here at TMC Engineering, we have a deep commitment to delivering projects characterized by the highest standards for safety, workmanship, and client satisfaction. Whether it’s gravel driveways with edging or parking lot striping, w e aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving, striping, sealing , or concrete work, we offer a full suite of transportation construction solutions. Look no further–we’ve got all you need and more!

Gravel driveways provide a cost-effective surfacing solution for rural properties and low-traffic areas. However, the loose material is susceptible to developing pits and potholes over time under regular vehicle use. Left unrepaired, these depressions only get bigger with continued rainfall and wheel traffic.

Not only can potholes ruin the appearance of a gravel surface, but they can make a driveway or parking area lose functionality. Large holes have the potential to damage tires, rims, and other vehicle parts. Injury is possible as well if the potholes are struck at a fast speed. So, all around, repairing potholes as quickly as possible is wise to uphold the safety and integrity of a gravel surface. Learn more about the causes of potholes in roads and parking lots here.

Today, we’re sharing our simple guide for fixing potholes in gravel driveways and parking areas to preserve functionality for years to come.

How To Fix Potholes In Gravel Driveway

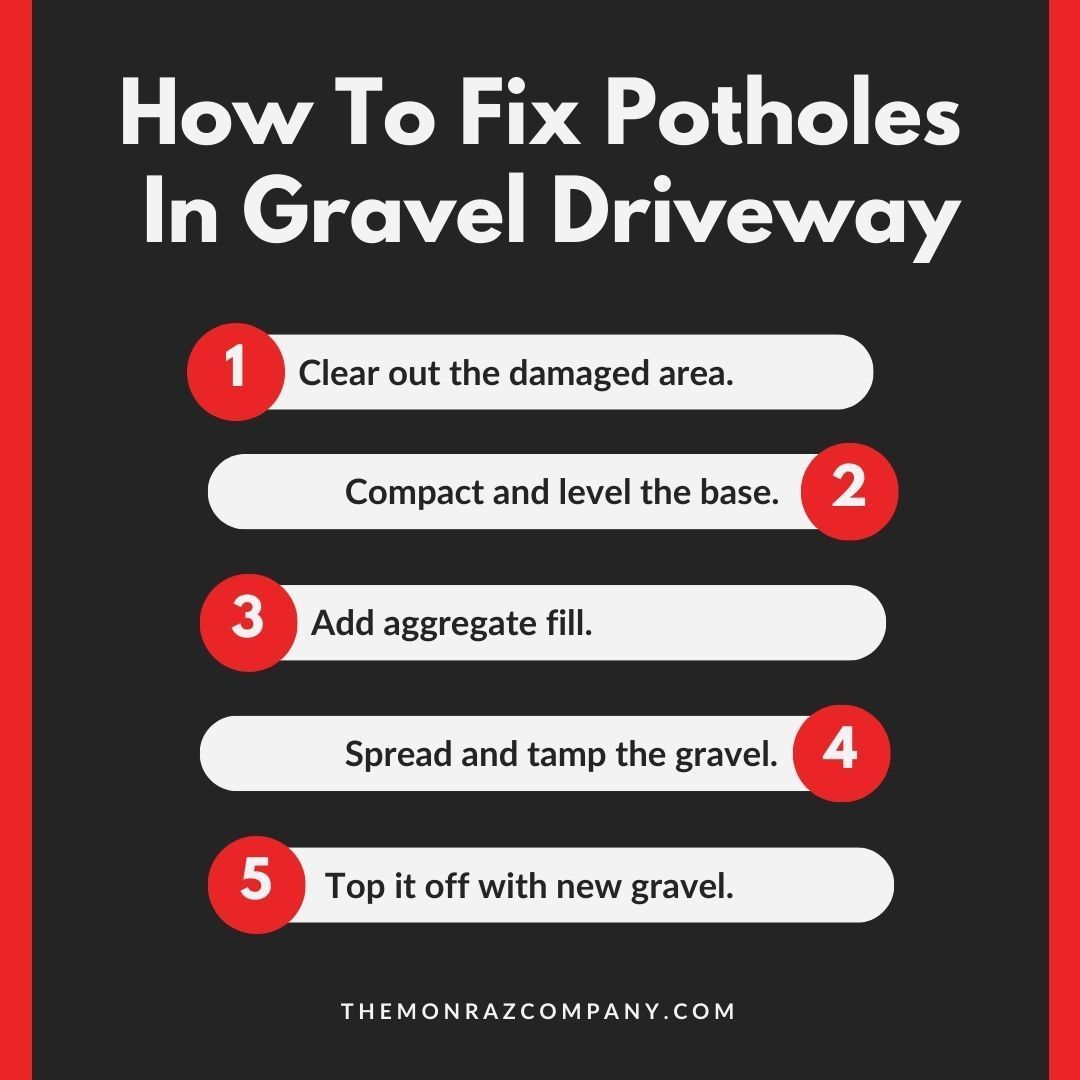

Successful pothole repair involves a step-by-step process to ensure a durable, long-lasting fix. Let’s examine each stage:

Step 1: Clear out the damaged area.

Use a shovel to excavate loose gravel and debris from inside and around the pothole. Remove all rubble and old filling until the solid base material below is exposed .

Step 2: Compact and level the base.

Use the shovel head or tamper tool to pack down and smooth the base material firmly. Fill in any sunken spots with gravel or any other compatible aggregate and establish an even surface.

Step 3: Add aggregate fill.

Pour fresh 3/4-inch gravel into the prepared hole in 4-6 inch lifts. Tamp after each pour to fully consolidate the material. Overfill slightly above the surrounding grade.

Step 4: Spread and tamp the gravel.

Use the tamper to spread fill gravel evenly over the repair area. Thoroughly compact in a grid pattern until completely consolidated and level with existing grade.

Step 5: Top it off with new gravel.

To finish, apply a thin 1/4-inch layer of fresh 3/4-inch gravel uniformly over the repaired area and several feet beyond. Tamp it lightly, level and the repair is complete!

How to Know It’s Time To Repair Your Gravel Driveway

Here are some key signs that indicate it’s time to repair a gravel driveway:

- Potholes : If you notice depressions or holes starting to develop in the gravel surface due to vehicle traffic or weathering, it’s a sign repairs are needed. Unchecked potholes will continue growing.

- Loose gravel : Over time, constant vehicle and foot traffic will cause the gravel material to break down and loosen. Signs like gravel washing off the sides or accumulating on lawns mean the binding material is compromised.

- Ruts or uneven wear patterns : Overtime, you may notice the gravel surface is no longer even, but instead there are deep wheel tracks or ruts from consistent traffic wear. Patches may be needed to re-grade problem zones.

- Edges sinking or deteriorating : The gravel edges along the shoulder may begin sinking lower than the main surface, allowing runoff and further erosion. Reinforcement is required.

- Drainage issues : Overtime as compaction fails, heavy rains can penetrate the gravel surface and wash away the finer particles. If not addressed, the drainage issue could dislodge larger stones and compromise the gravel driveway’s integrity.

- Significant gravel loss : If over 30% of the original installed gravel thickness has washed or worn away, the base needs rebuilding with fresh aggregate.

- Safety concerns : Loose gravel, potholes, or heavy rutting pose potential trip or vehicle damage hazards that require repairing.

Consistent yearly inspection catches smaller issues before they worsen. Addressing problems promptly saves repair costs down the road.

Tips on How to Repair Potholes in Your Gravel Driveway

Preparation is key.

When implementing repairs, careful base preparation proves just as important as refilling the hole properly. Thoroughly removing defective material allows for well-compacted, load-bearing support beneath the new aggregate.

Use the right replacement methods.

Replacing gravel in thin layers and adequately compacting each lift with a compactor mimics how the driving surfaces were originally installed. Using a compactor ensures the surface withstands sustained traffic and premature sinking doesn’t occur.

Choose the right materials.

For patching aggregates, you will find that a 3/4-inch gravel provides necessary grip for most repair jobs and stays in place better than finer material. If the fill looks noticeably different even after compaction, you can feather in the new gravel using a rake. This way, there will be no discernable difference in color or texture.

Use the right tools.

While a basic gravel yard rake or shovel handles general cleanup and excavation, compacting subbases to sufficient densities requires more specialized tools. For small patches, we recommend renting a manual plate compactor and for large jobs, locate a commercial-grade vibratory compactor.

Consider other alternatives.

The truth is, gravel lanes or parking areas will require routine patching and full-scale reconstruction is inevitable if the surface sustains regular use. If you’re looking for an option that requires less maintenance, consider asphalt or concrete pavement as an alternative. Both can withstand intensive wear and have few of the drawbacks of a gravel surface. If you’re in the Southern California area and are ready to invest in a concrete or asphalt driveway or parking area, contact us for a FREE QUOTE .

The right knowledge and tools make fixing potholes in a gravel driveway easy.

Potholes are inevitable when maintaining a gravel surface. However, potholes can be quite easy to fix and with timely repair, you can prevent further damage and dangerous conditions on your gravel driveway or parking area. Use these tips to ensure your pothole repair is effective, and consider upgrading your area to an asphalt or concrete surface that will be more durable and functional while requiring less maintenance.

Here at TMC Engineering, we have a deep commitment to delivering projects characterized by the highest standards for safety, workmanship, and client satisfaction. Whether it’s gravel driveways with edging or parking lot striping, we aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving, striping, sealing, or concrete work, we offer a full suite of transportation construction solutions. Look no further–we’ve got all you need and more!