How To Patch Holes In Concrete

Concrete is known for its strength and durability, making it one of the most widely used construction materials in the world. Its hardened composition lends an impressive level of resistance to damage, wear, and environmental effects . However, even concrete floors are susceptible to developing small cracks and holes over time due to improper finishing, weathering, or unexpected damages as discussed in our post “ When Can You Pour Concrete? ”.

The causes of holes in concrete can vary from normal weathering cracks to unexpected accidents and impacts. Constant exposure to freeze-thaw cycles and shifts in temperature can gradually weaken concrete joints as well . Roots from nearby trees or shrubs may also create fissures as they grow. In some cases, holes are the result of trip-and-fall incidents or inadvertent strikes from vehicles in parking lots.

While unsightly defects pose no serious threat to a concrete slab’s structural integrity in minor cases, larger openings may compromise usefulness or create potential safety hazards. The good news is that patching concrete holes is usually a straightforward repair process when done properly. For homeowners and contractors alike, filling voids through basic patching techniques can help prolong a slab’s functional lifespan by many years.

In this comprehensive guide, we will provide a step-by-step approach to repairing cracks and holes of different sizes in concrete surfaces. And, although you may feel confident in your abilities to execute your repair, we always recommend first consulting the professionals at TMC Engineering !

Let’s get started!

How To Patch Holes In Concrete

How to Patch Small Holes in Concrete

Small holes or defects less than an inch wide can typically be filled using a simple concrete patching compound or filler. These products are clean and easy to use for minor repairs that don’t require extensive work. Ensure any debris is removed from the hole first for proper bonding of the new material.

How to Patch Large Holes in Concrete

For filling holes or fractures over an inch wide in a concrete foundation , typically a more robust repair technique is required . Large voids may need formwork installed and refilling done in lifts, or epoxy resins can bond reinforcement for strength. Proper hole preparation is critical for these types of repairs to endure long-term usage and loading stresses.

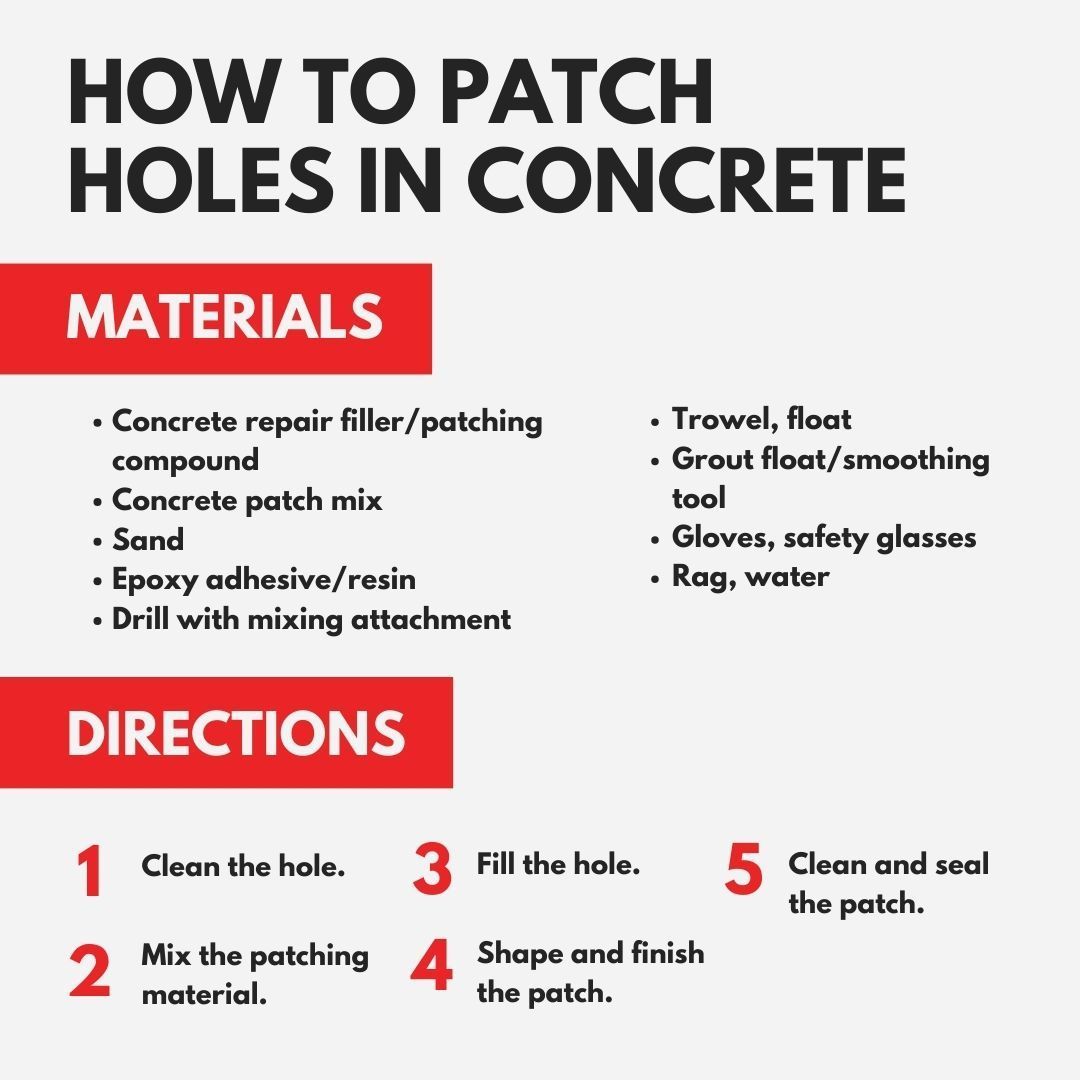

Materials

- Concrete repair filler/patching compound

- Concrete patch mix

- Sand

- Epoxy adhesive/resin

- Drill with mixing attachment

- Trowel, float

- Grout float/smoothing tool

- Gloves, safety glasses

- Rag, water

Directions

Step 1: Clean the hole.

Use a wire brush to thoroughly scrub inside the hole and roughen the edges. Vacuum and wipe away all dust and debris. Dampen with a clean, wet rag and allow excess water to evaporate fully before proceeding.

Step 2: Mix the patching material.

For dry patching compounds, follow label directions for water ratio. Mix to a creamy peanut butter consistency before use. Epoxies come pre-measured for the hole size and require stirring both parts together as instructed.

Step 3: Fill the hole.

Pack patching material firmly into the hole using a trowel, working from the bottom up in thin layers. Overfill slightly and allow to fully cure as directed before proceeding to the next step.

Step 4: Shape and finish the patch.

Once cured, shave off any excess concrete above the surface using a margin trowel. Wet and smooth with a magnesium float trowel or grout float for a seamless finish, and feathering edges.

Step 5: Clean and seal the patch.

Once fully dried, wipe away any residue with a clean, damp rag. Apply a high-quality concrete sealer to the patch and surrounding area for protection and to blend in aesthetically.

Tips For S ealing S mall and L arge H oles

Small scratches and holes under 1⁄2 inch can usually be patched on the same day. For larger repairs, follow the compound directions for curing before allowing traffic or water contact. Patching like professionals does require some tricks as discussed in our post on concrete parking lot repair .

Here are some additional best practices:

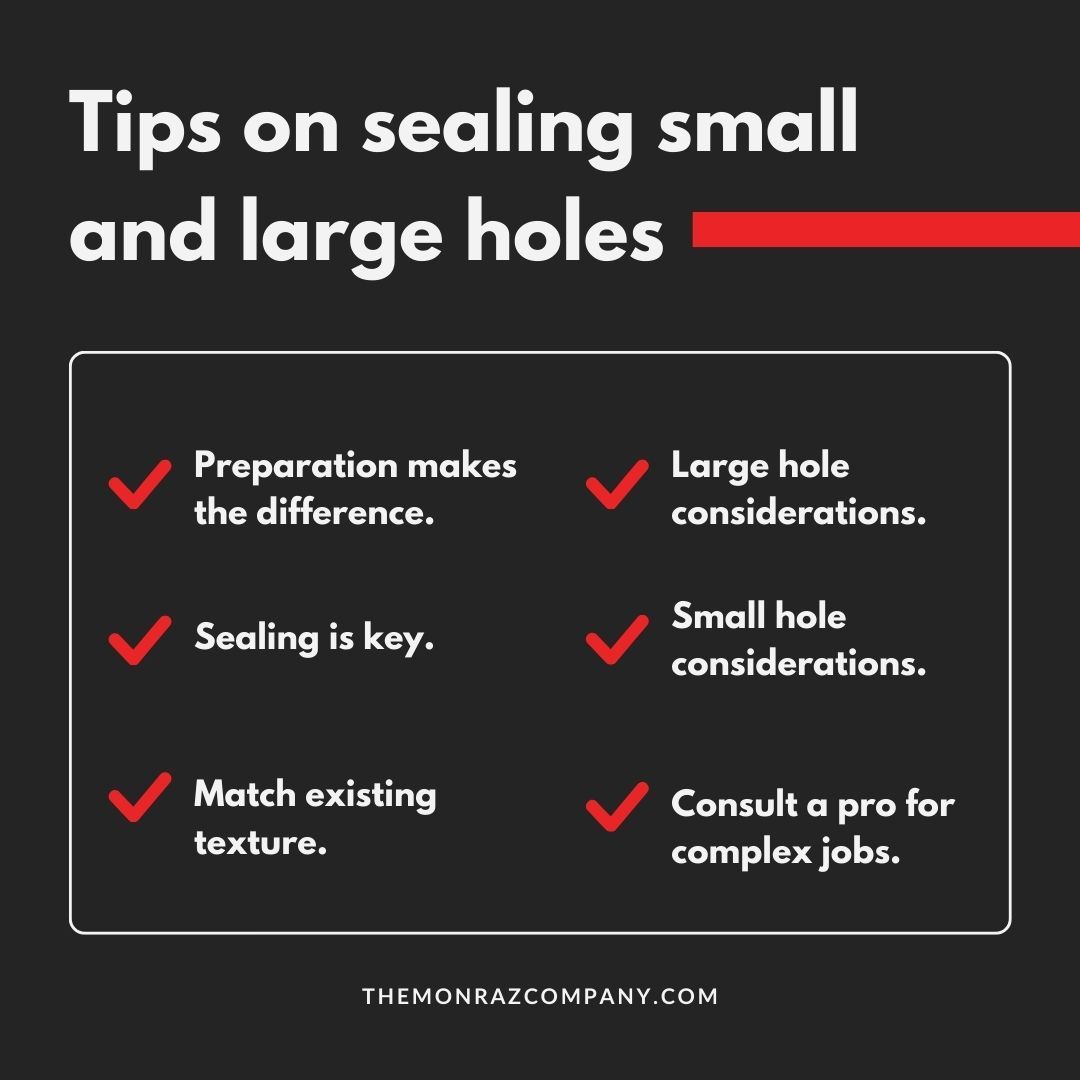

Preparation makes the difference.

Thoroughly cleaning and roughening the hole edges cannot be emphasized enough. Proper preparation allows for maximum adhesion of the new patching material.

Sealing is key.

Sealing patched areas guards against future cracking or spalling from exposure. A high-quality penetrating sealer provides an important final layer of protection.

Match existing texture.

Float patching to reproduce the surrounding concrete’s sand finish. Or brush in decorative stamping for an invisible repair. This blending camouflages the patchwork.

Large hole considerations.

Form pockets larger than 2 inches using fast-setting concrete for structural integrity as professional contractors would for foundations. Multiple lifts and epoxy reinforcement strengthen deep holes.

Small hole considerations.

Minor defects under 1⁄2 inch in size pose no risk when patched by DIYers using basic patching compounds as directed. Ensure protection from traffic or rain until fully cured.

Consult a pro for complex jobs.

Challenging repairs involving rebar, extensive cracking, or load-bearing areas are best left to experienced concrete contractors. Their specialized tools deliver quality, long-lasting outcomes.

With the right knowledge, tools , and expertise, patching holes can be made easy.

In summary, patching holes in concrete is a practical solution for restoring damaged slabs and extending their usable lifetimes. With just a few basic materials and proper techniques, even large openings can be repaired strategically. For homeowners, addressing small defects promptly prevents further deterioration that leads to costly replacement jobs.

By following the guidance provided here, anyone can perform simple patchwork that blends invisibly and protects concrete from future water intrusion or stress. Regular maintenance like patching preserves functional surfaces and curb appeal for many more productive years of service.

With a bit of know-how transferred in this guide, taking on small concrete repairs need not be an intimidating or expensive prospect. Finding the right materials and ensuring thorough preparation and sealing are the real keys to success.

Here at TMC Engineering , we have a deep commitment to delivering projects characterized by the highest standards for safety , workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further–we’ve got all you need and more!