Paving Temperatures: Minimum and Maximum Temperatures For Paving

Among the many factors that determine the quality of an asphalt pavement installation, temperature is one of the most important! The slightest changes or miscalculations i n temperature during the mixing, laying or compaction stages can significantly impact the end result. For example , insufficient heat can prevent the asphalt from bonding fully, while excess heat may cause it to set prematurely without proper densification.

As paving contractors , we’ve witnessed firsthand how sensitive the asphalt process is to temperature variations. A difference of just a few degrees one way or the other can translate to issues like cracking, permeability or reduced longevity down the road. This is why ensuring the asphalt mixture and ambient air meet narrow temperature thresholds is essential for compaction success!

So, what are the optimal temperature requirements for asphalt paving? Today, we want to focus on establishing clear guidelines for minimum and maximum temperature requirements when it comes to paving. Understanding these temperature parameters is vital for obtaining a durable, high-quality asphalt installation whether for a parking lot, driveway or other project!

Let’s explore the temperature dos and don’ts of asphalt mixing, laying and compaction.

Paving Temperatures: Minimum and Maximum Temperatures For Paving

Each step, from heating the asphalt mixture to complete curing of the new parking lot or driveway, has an optimal temperature range that must be followed.

Asphalt Melting Temperature

The process begins by melting the asphalt cement at the mixing plant. This crucial first step requires heating it to 300-350°F to completely liquefy the material and allow for proper blending. Heating b elow 300°F risks incomplete melting of the cement.

Asphalt Mixing Temperature

The hot mix asphalt mixture needs to be at least 185°F when it leaves the plant. This temperature can vary to as high as 300°F. This ensures the asphalt is hot enough to lay and compact properly but not so hot that it cools too quickly. Infrared thermometers are used by pavers to check the mix temperature regularly.

Asphalt Laying Temperature

Once the hot asphalt mixture leaves the plant, pavers then lay down the fresh material. The ground temperature, or ambient temperature, should be at least 50°F and rising when you want to lay asphalt. Any lower and the cool asphalt won’t bind and compact correctly, potentially leading to issues.

At this stage, the optimal temperature range is 230-300°F. Going below 230°F causes the asphalt to cool too quickly before proper compaction can occur. On the other hand , exceeding 300°F increases the chance the asphalt will begin to harden up prior to densification by rollers.

Asphalt Compaction Temperature

Hitting the right temperature range during compaction is important for creating a pavement built to last. Compactors must work the hot asphalt mixture between 180-240°F for the asphalt to properly compact. Within this zone, the material can properly bind together without any potential for segregation of its components or becoming sticky.

Proper compaction is vital for a strong and durable asphalt pavement. This requires the asphalt to be hot enough to compact but not too hot that it doesn’t bind firmly. Once compacted, the new pavement needs enough heat to prevent premature cooling that could cause cracks to form.

Asphalt Curing Temperature

Even after compaction is complete, the asphalt continues to cure as it fully cools. This requires maintaining temperatures above 100°F to ensure full and correct curing of the pavement. Below 100°F there are risks of incomplete bonding or early cracking.

Importance of Temperature Monitoring During Asphalt Paving

Ensuring proper temperatures throughout the asphalt installation process is absolutely crucial for constructing a pavement primed to withstand the test of time. Even slight fluctuations outside the optimal ranges can undermine quality and longevity , which is why vigilant temperature monitoring at each stage is so important!

Temperature affects the following factors:

Bonding St rength

Sticking within temperature parameters ensures the asphalt fully bonds together in its molten state and solidifies into a cohesive whole. Deviations could leave behind weaknesses where aggregate doesn’t completely adhere to cement. Over years of heavy loading from vehicles, these weak points become prone to cracking or chunking out.

Pavement S moothness

Consistent temperatures from start to finish are also critical for a uniform, well-consolidated surface free of bumps and gouges. Wide variations make it tougher to achieve uniform compaction across the paving site, potentially resulting in an uneven, rough pavement and accelerating wear of tires and suspension. This, in turn, may lead to extra maintenance costs.

Material Consistency

Fluctuations throughout the blending, transport and laying intervals can cause shifts in the asphaltic concrete mix proportions, as components don’t react identically outside optimal heating zones. Composition changes translate to inadequacies like permeability, stripping or early failure under traffic.

Long-term Workability

Keeping temperatures within specified limits during placement and subsequent compaction adjusts the material’s workability for seamless construction. This ensures it can be thoroughly densified before fully setting without sticking issues, segregation of elements or cold joints.

Durability

Adherence to temperature specifications during all phases, from initial heating to complete curing, facilitates proper solidification of a tough, wear-resistant and flexible surface. A pavement installed this way stands up to intensive use for many decades to come with low maintenance demands.

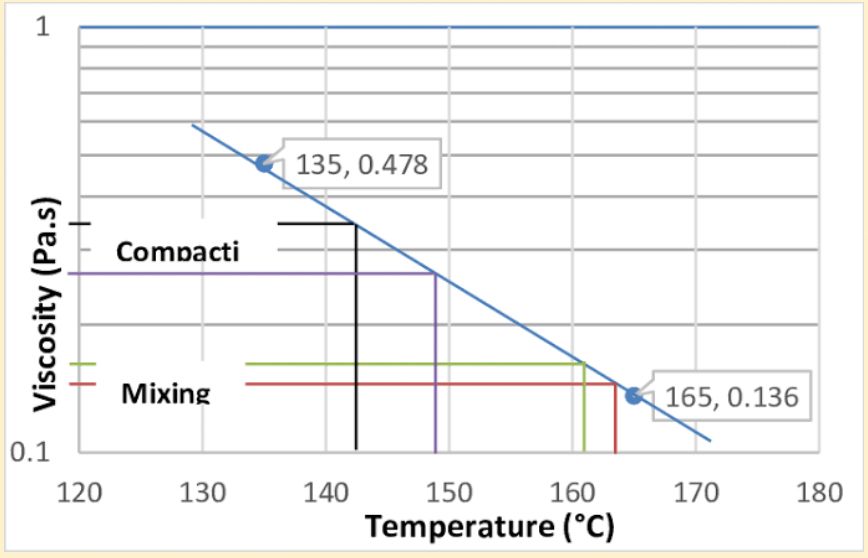

Asphalt Temperature Chart

By carefully monitoring temperatures throughout the paving process using infrared thermometers, pavers can lay only hot asphalt mixtures that achieve full compaction for a durable asphalt road, parking lot or driveway.

Adhering to these optimum temperature thresholds leads to an infrastructure that will serve its purpose for many years to come. Precise temperature management is thus necessary to fully guarantee the asphalt’s structural integrity now and well into the future. Consistent monitoring using such tools as infrared thermometers allows obtaining this level of quality assurance.

At TMC Engineering, we’re committed to quality and safety alongside other needed metrics for excellence. Stay tuned for even more informative posts and exciting updates from our page . In need of a wide range of services from asphalt paving to striping, sealing, crack filling , and concrete projects ? Look no further! TMC Engineering has got you covered. Contact us today for a free quote ! Together, we can complete exceptional projects that stand the test of time!