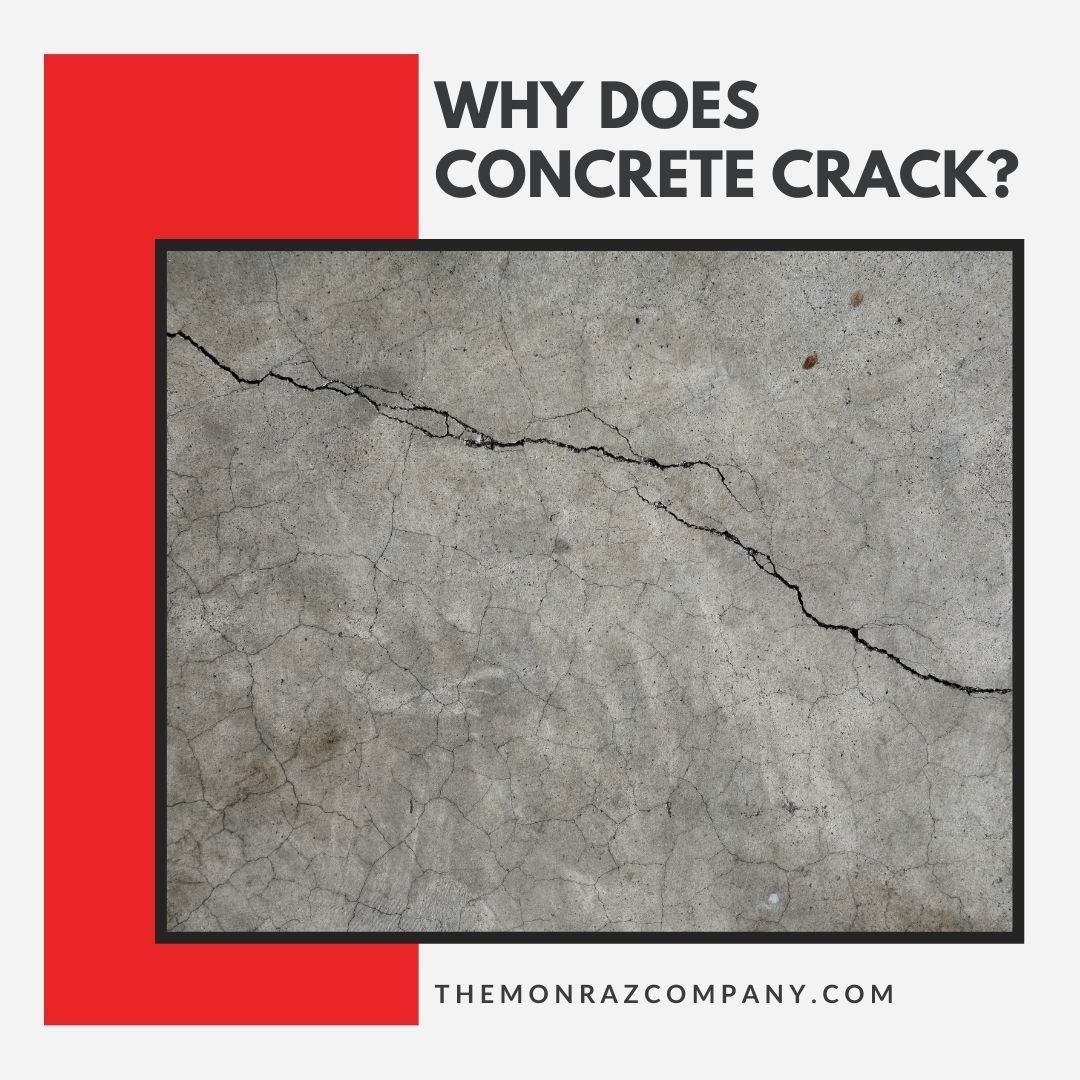

Why Does Concrete Crack?

Concrete is one of the most widely used construction materials in the world due to its strength, durability and versatility as a building and paving material. When poured and cured correctly according to design specifications and industry standards, concrete structures can withstand considerable stresses and last for many decades.

However, it’s also quite common over time for cracks to slowly develop in concrete surfaces such as foundations, floors, walkways, and driveways. While concrete maintains its structural integrity even with minor cracking in many cases, unchecked cracks can progressively worsen if left unaddressed. This can potentially compromise the surface aesthetics, as well as allow water and salt intrusion that leads to further deterioration and repairs down the road.

In this post, we will examine the various reasons why cracks occur in concrete surfaces, slabs and other structural elements. Understanding the root causes is important, as it can help when taking preventative measures during initial construction or renovation work.

If you’d like a quicker or more specific answer to your cracked concrete question, call the experts at TMC Engineering ! If you’re in Southern California, we can help educate you on your problem and perform whatever repair is necessary. We’ve got an expert solution for your concrete or asphalt concern!

Why Does Concrete Crack?

There are several reasons why cracks may develop in concrete. Here are some of the most common reasons for cracking and various types of concrete cracks:

Shrinkage Cracks

As the water within freshly poured and placed concrete begins evaporating, the concrete mixture begins shrinking inward while hardening. This causes shrinkage stresses that sometimes result in fine surface cracks, known as plastic shrinkage cracks . These stresses can be exacerbated in windy, dry or hot weather conditions that accelerate the water loss. Proper wet curing methods will help to reduce risk of shrinkage cracking. However , without expansion joints or reinforcement, these stresses from shrinkage can lead to cracking.

Settlement Cracks

When moisture or vibration causes unequal settling of the subsurface layer underneath new concrete slabs or floors, horizontal cracks may form from the differential foundation movement. Uneven settling stresses the upper concrete surface, leading to fractures. This is what is defined as settlement cracks. Tree roots can also cause cracks from expansion. Thorough compaction of subgrade materials can help prevent such settlement issues.

Temperature Cracks

Expansion and contraction occurs in concrete as temperatures fluctuate over time, as the material absorbs and releases heat. If the concrete hardens and is unable to expand or contract freely due to restraints, thermal stresses can overwhelm the concrete strength and cause cracking. Proper use of control joints helps manage temperature stresses to prevent cracking.

Drying Shrinkage Cracks

Concrete slowly shrinks as it undergoes multiple hydrating and drying cycles over several months or years. This can cause the concrete to shrink in volume, creating internal stresses within the concrete, leading to cracks.

Cracks From the Mix Design

Concrete requires mixing before application, and if the concrete ingredients are not properly balanced, it can cause cracking. For instance, if the proportions of water, cement, aggregate, or other additives aren’t just right, it can weaken concrete and make it prone to cracking.

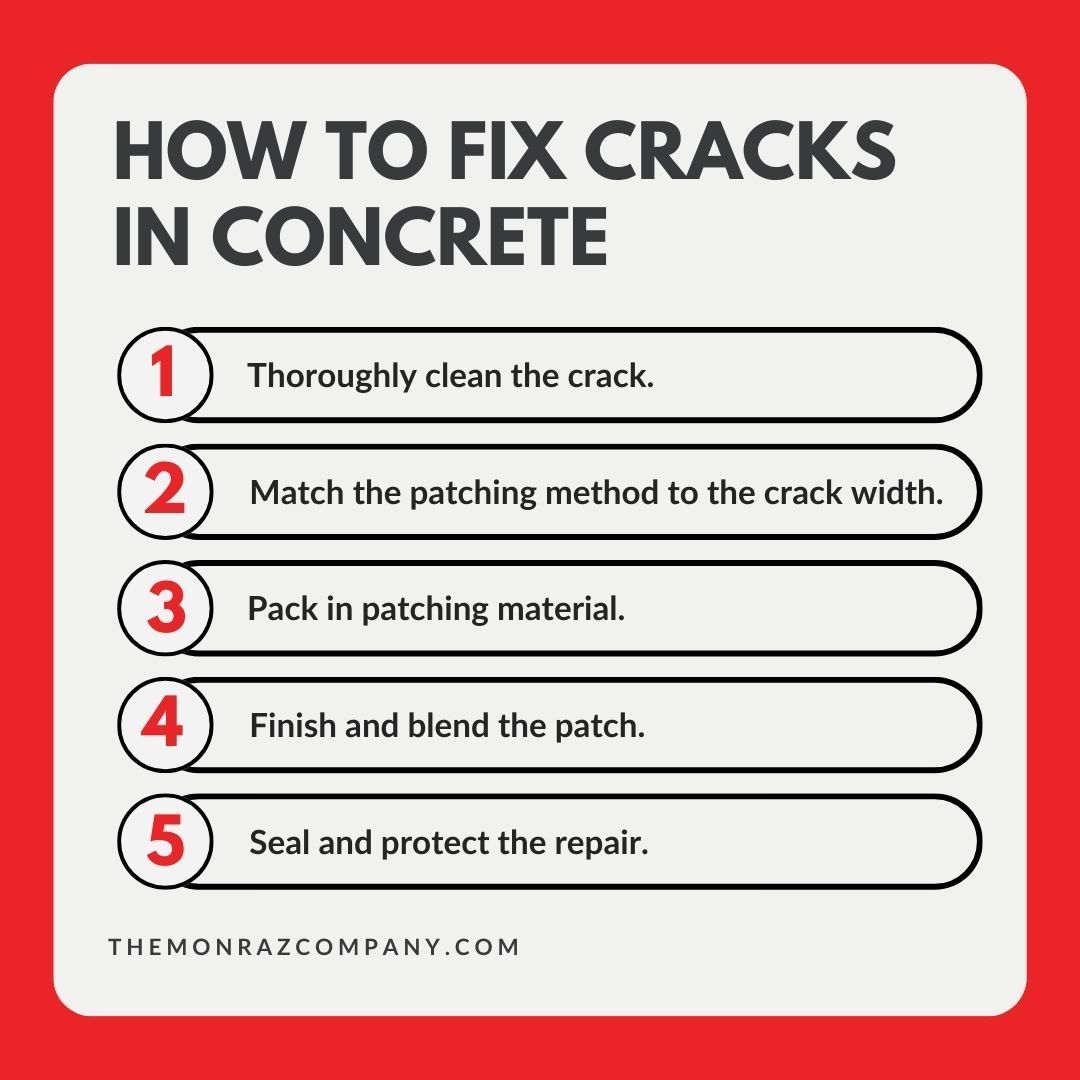

How To Fix Cracks in Concrete

When cracks do inevitably occur in concrete, it’s important to address them properly to avoid further deterioration. By following some simple best practices, you may be able to successful remedy your concrete parking lot repair job. But, as always, it’s best to consult a professional!

Step 1: Thoroughly clean the crack.

Always start by using wire brushes or grinders to thoroughly scrub cracks free of debris, dirt, and other contaminants as discussed in our post on how to patch holes in concrete. This prep work allows for the proper bonding of the new patching materials.

Step 2: Match the patching method to the crack width.

For hairline cracks up to 1/4 inch, use flexible concrete caulk. Wider cracks may require packing with a patching compound or epoxy injection depending on the severity.

Step 3: Pack in patching material.

Whether using caulk, compound, or epoxy resins, carefully packing the filler into the crack helps produce durable repairs. Ensure you use the produce instructions to confirm you’re packing correctly!

Step 4: Finish and blend the patch.

Once cured, use trowels and float tools to shape, smooth, and blend the patch into the surrounding concrete. You can read more about this in our post on how to patch holes in concrete .

Step 5: Seal and protect the repair.

As a final protective measure, apply a high-quality sealer over the entire repaired area. Taking this repair all the way to the final stage of sealing is essential to a long-lasting repair.

By addressing even small cracks immediately, you can avoid further deterioration from water or weather damage.

Concrete cracking is a common occurrence that results from a variety of factors such as shrinkage during curing, foundation settling, thermal expansion, contraction stresses, gradual drying shrinkage, and improper concrete mix design. While cracking does not always pose a structural threat, it can accelerate deterioration if left unaddressed. Understanding these processes enables contractors to design and install crack-resistant concrete initially with reinforcement and properly placed expansion joints.

For cracks that occur, it is important to inspect structures regularly and make repairs promptly before issues worsen. By carefully cleaning cracks, selecting patching materials suited to crack widths, and properly finishing and sealing repairs as outlined, commercial property owners and contractors can achieve durable and long-lasting solutions. This preservation approach extends the functional lifespan of affected concrete elements like those found in parking lots and foundations.

Here at TMC Engineering , we have a deep commitment to delivering projects characterized by the highest standards for safety , workmanship, and client satisfaction. We aim to provide you with valuable content and insights related to the services our team of experts provides! Whether you require asphalt paving , striping, sealing , or concrete work , we offer a full suite of transportation construction solutions. Look no further–we’ve got all you need and more!